Advantages and Disadvantages of Screw Type Chiller vs Centrifugal Chiller

Centrifugal chillers

Advantage:

The impeller has a high rotation speed, large gas transmission volume, and large single machine capacity.

Fewer wearing parts, reliable work, compact structure, stable operation, small vibration, and low noise.

The weighted index per unit cooling capacity is small.

No lubricant is mixed in condenser the refrigerant, and the removes heat entering the evaporator and the condenser is good.

The EER value is high and the theoretical value can be reached. 6.996. Easy adjustment, stepless adjustment within 10% ~ 100%.

Disadvantages of centrifugal chillers:

The single-stage compressor will appear “surge” phenomenon at low load and run smoothly at full load.

Centrifugal chillers Strict requirements on material strength, processing accuracy, and manufacturing quality.

When the operating conditions deviate from the design conditions, the efficiency decreases faster, and the cooling capacity decreases faster than the piston type as the evaporation temperature decreases.

Centrifugal negative pressure system, outside air, is easy to invade, there is a risk of chemical changes corroding pipelines.

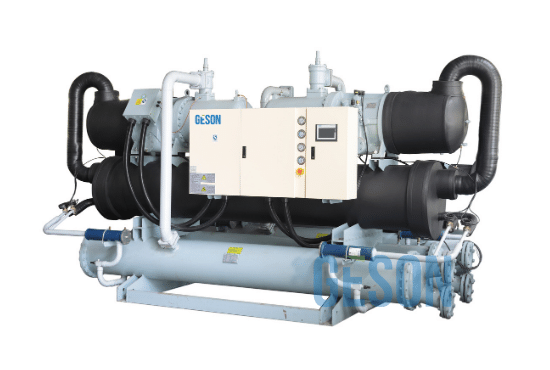

GESON 500Tons Inverter Direct-drive Centrifugal Chiller

Cooling capacity: 250~1300RT / 879~4571kW

Refrigeration COP: 6.33~6.62

Refrigeration IPLV: 8.10~9.07

Energy Efficiency Level: Level 1

Dimensions (LxWxH): 3650x1940x2150~4800x2260x3050mm

Shipping weight: 4650~13650kg

Running weight: 5580~16710kg

Cooling capacity: 250~1300RT / 879~4571kW

Refrigeration COP: 6.33~6.62

Refrigeration IPLV: 8.10~9.07

Energy Efficiency Level: Level 1

Dimensions (LxWxH): 3650x1940x2150~4800x2260x3050mm

Shipping weight: 4650~13650kg

Running weight: 5580~16710kg

500Tons Inverter Direct-drive Centrifugal Chiller

- Cooling capacity: 250~1300RT / 879~4571kW

- Refrigeration COP: 6.33~6.62

- Refrigeration IPLV: 8.10~9.07

- Energy Efficiency Level: Level 1

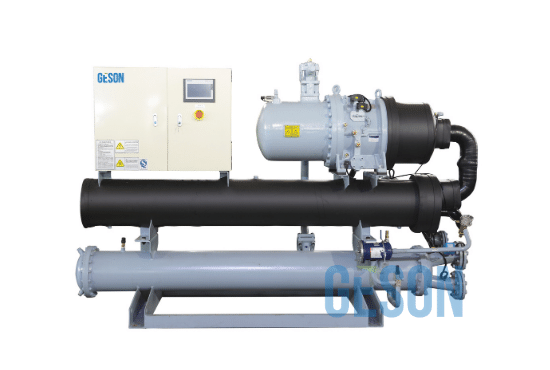

What is Centrifugal Chiller?

A centrifugal chiller is a device that is used in order to cool water. The design of the centrifugal chiller is such that it has a rotating impeller that forces water through a tube and then out into the atmosphere. The rotation of the impeller creates an area of low pressure on the inside of the tube, which causes cold water to be drawn in from outside and pumped through the tube.

The centrifugal chiller can be used in many different industries, including food processing plants, breweries, and chemical plants. There are two types of centrifugal chillers: internal and external. External chillers are usually placed outside so as to allow for easier access by workers or for easier connection to other devices like pipes or pumps. Internal chillers are usually smaller and more compact than

What is the difference between chiller screw type and centrifugal chiller?

Screw type chiller and centrifugal chiller are two types of chilling equipment. Chiller screw type is a more traditional type of equipment. It works by cooling the water that goes into it, which in turn cools the food and beverages.

Centrifugal chiller on the other hand, is a newer type of technology. It works by spinning a cylinder filled with ice around to cool the water in it and then pumps that cold water onto the food or beverages that need to be cooled.

The only difference between these two types of chillers is how they work. They both have their pros and cons but typically screw chillers are used for smaller production volumes while centrifugal chillers are used for larger production volumes.

Which type of chiller is best?

A screw type chiller is a type of chiller that uses a coiled tube to cool water. The coil is usually made of copper, but it can be made out of other metals, such as aluminum. A screw type chiller is best for cooling small amounts of water to a moderate temperature.

A centrifugal chiller is a type of chiller that uses centrifugal force to cool water. The water enters the machine through the inlet and then exits through the outlet pipe. A centrifugal chiller is best for cooling large amounts of water to a high temperature.

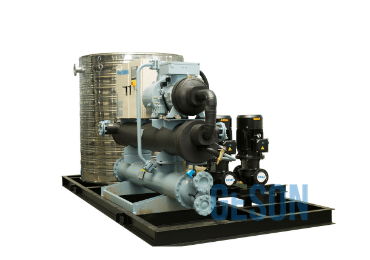

All Types of Industrial Water Chiller Products

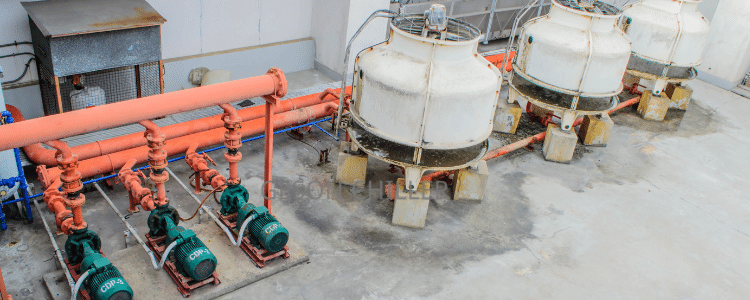

Geson water cooled chillers and air cooled chiller product range cover Industrial Process Chillers Refrigeration and Commercial Central air-conditioning, including Water cooled chillers, Air cooled chillers, Screw Chillers, Scroll Chillers, Centrifugal chillers, Water(ground) source heat pumps, Air source heat pumps, Absorption chiller, mechanical compressor, Cooling Towers and etc., Capacity from 2tons~4000tons, and temperature from -160℃~30℃, complete full right chiller product series, air or water cooled for customers.

Geson Industrial processes chillers involve all chiller types, and you can do chiller selection according to chiller types, operating cost, energy efficiency building load, energy consumption, variable speed, compressor technology, operating time, part load, air or water-cooled chiller types, fully serviceable or less equipment, maintenance costs, whether need large buildings, so also can design from the building owners advice.

Read more about GESON industrial chiller manufacturer, industrial process chiller manufacturers, water cooled chillers, get multiple chillers, air cooled chillers offer for you, pls visit www.linkedin.com/in/gesonchiller