- 5RT-4000RT Capacity

- -5~25℃ Outlet Temperature

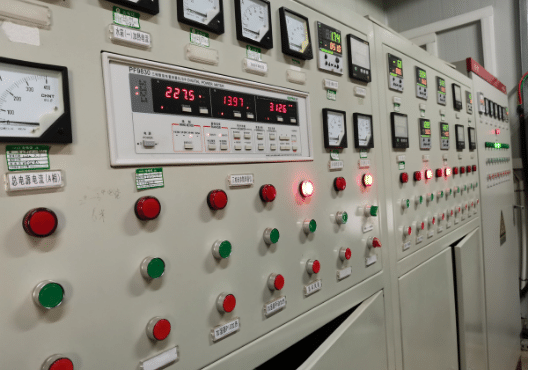

- PLC Controller

- No Need Cooling Tower

- Easy to Installation

- Ranges from 50TON~4500TONS.

- Famous Leading Screw Compressor Brands;

- Stable Operating Performance;

All Types of Industrial Water Chiller Products

Modular Air Chiller

Applications

Chiller For Plastic Industrial

Beer And Wine Fermentation Chiller

Chemical Processing Chiller

Computer Data Center Chiller

Food And Dairy Chiller

Hotel HVAC Chiller

MRI And Laser Chiller

Pharmaceutical-Formulation-chiller

Swimming-Pool-chiller

Why Choose GesonChiller?

Are you looking for a professional water chiller manufacturer?

Geson chiller focuses on Industrial/Commercial water chiller over 15 years.

Offers one-stop water chiller solutions with the highest quality and safest products to customers globally.

You can get the water chillers capacity from 3 Ton~4500 Ton, and temperature from -145℃~25℃, complete full product series for customers.

Including Water cooled chillers, Air-cooled chillers, Screw Chillers, Scroll Chillers, Centrifugal chillers, Water(ground) source heat pumps, Air source heat pumps and etc.

Geson chiller has is widely applied in the Commercial facilities, Pharmaceutical clean room, Chemical industry, Plastic Injection, and extruding industry, Artificial Real Ice Rink projects, Environmental simulation laboratory, Computer server room, Telecommunications stations, Food and Beverage processing cooling, Cold storage room, Die casting, Rubber, Printing, and many other industries.

Geson has been exported to the Americas, Europe, Middle East, Africa, Southeast Asia, and its, and was praised by customers all over the world.

If you have more questions about water chillers, free to contact us.

| Air-Cooled Screw Chiller | ||||

| No. | Item | Unit | 225kw | |

| 1 | Rated Cooling Capacity | KW | 225 | |

| kcal/h | 193500 | |||

| RT | 64 | |||

| 4 | Capacity control | % | 0-25-50-75-100 | |

| 5 | Evaporator | Evaporator | Shell and tube type | |

| Evaporator import and outlet diameter | DN | 200 | ||

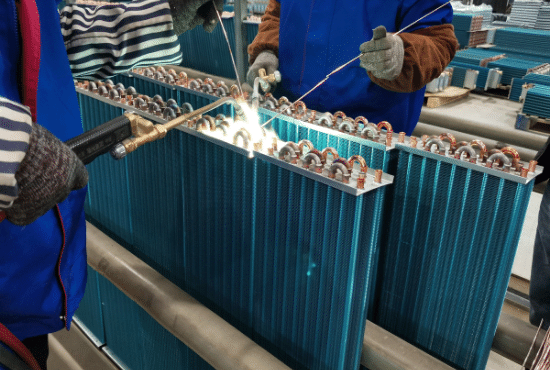

| 8 | Condenser | Efficient copper pipe and aluminum foil compact type finned heat exchanger | ||

| 9 | Refrigerant | R134A | ||

| 10 | Power specification | 3P-380V-50HZ | ||

| 11 | Protection device | Phase lack protection, phase reversion protection, overload current protection, exhaust temperature protection, low&high pressure protection, low temerature protection. | ||

| 12 | Size | MM | L9000X W2200 X H2500 | |

| 13 | Weight | KG | 7400 | |

| 14 | Operating Weight | KG | 8000 | |

Advantages of Geson Chiller

We want to be your expert chiller manufacturer in China

Your Top Quality Chillers Manufacturer In China

Top Brand Components

Ensure Your Top Quality Chiller

Screw Chiller Manufacturer in China | Geson Chiller

The demand for energy-efficient cooling systems in commercial and industrial buildings has given rise to advanced HVAC systems. The use of a screw chiller is an example of how high-rise buildings have evolved when it comes to cooling installations. This FAQ guide will detail all the information you need to know about a screw type chiller so you can determine if this is the best fit for your cooling needs.

What Is a Screw Chiller?

A screw chiller is designed for industrial and commercial use. This type of chiller is made with a screw chiller compressor and has large load cooling capacity. This makes it an ideal choice for cooling industrial and commercial buildings.

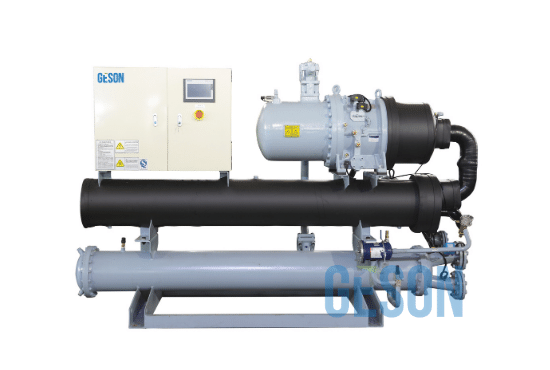

Screw Type Chiller

What is the Components of a Screw Chiller?

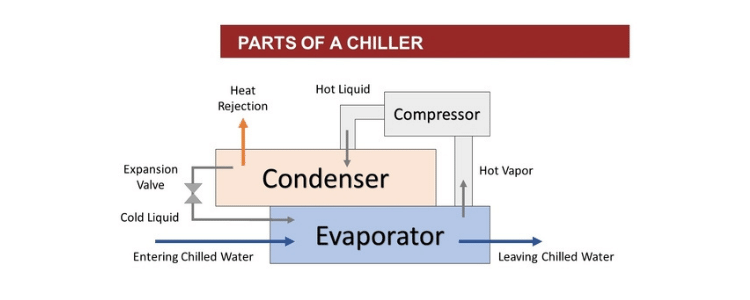

It is similar to other chiller systems in terms of parts: screw chiller compressor, evaporator, condenser, and expansion valve. However, it differs from other types in terms of the type of compressor operation – screw type (as the name implies). This compressor involves the use of dual helical rotors that processes the refrigerant vapor.

Water Screw Chiller Components

How about the Screw Chiller Advantage?

This type of chiller is deemed more durable and creates less noise since there are less moving parts involved. In addition, it tends to be smaller and more lightweight than other types of chillers. All of these factors combine to make a rotary screw chiller more popular than other types in the market without compromising its heavy duty performance. You can rely on it even when used under harsh conditions or tough environments. It is, therefore, a wise investment for commercial and industrial use.

What Are The Benefits of Screw Type Chiller?

There are plenty of benefits that you can get when you choose a screw water chiller, which also makes it a popular choice across various industries. One of the major advantages you get to enjoy with its use is that there is less possibility that it will break down. There are two moving parts involved with this type of chiller. These two parts do not come in contact with each other so there is less likelihood of them getting damaged over time since it won’t suffer a great deal of wear and tear.

How do the Screw Chiller Operation?

Screw Chiller Maintenance Checklist:

1. Inspection and preparation before daily start-up

1. Start the chilled water pump;

2. Turn the three-position switch of the chiller to the “wait/reset” position. At this time, if the flow of chilled water through the evaporator meets the requirements, the status indicator light of the chilled water flow will be on;

3. Confirm that the spool valve control switch is set in the “automatic” position;

4. Check the set value of the chilled water supply temperature, and change the set value if necessary;

5. Check the current limit set value of the main motor, and change the set value if necessary.

Screw Air Cooled Chiller

What is the Advantage of Screw Chiller?

Another advantage you can get is that it can operate continuously without any glitch. First and foremost, the parts are less likely to suffer from wear and tear and they operate without any noise. These factors make it possible to run the system for 24 hours straight. You won’t have to worry about it suffering from damage so you can experience no disruption to your commercial or industrial activity. Not only that, it is very resilient so you can expect it to last up to 5 times longer than other types of chiller with proper care and maintenance.

Screw Water Chiller

How the Screw Chiller Operating Performance?

Even if you operate this for 24 hours at a time, you won’t have to worry about your utility bills going up. It is efficient and energy consumption saving. You can, therefore, generate more air flow while using less power. This particular feature makes it suitable for use on machines with over 20HP capacity. Lastly, it is also compact in size. This makes it lighter and ideal for use on a sealed compartment.

Are There Any Drawbacks to a Screw Chiller?

While there are plenty of advantages that you can get with the use of a screw compressor chiller, there are also a few things you need to be on the lookout for. Given the benefits that you can get, expect to pay a higher price for this type of chiller. It is more expensive than a piston compressor operation since the parts are more expensive.

What Need to Care of Screw Water Chiller System?

Another downside to the use of a screw type chiller is that it requires higher lubricant consumption. Its use of a complicated lubricating system enables it to endure for many years even with regular use. At the same time, the installation process is quite complicated. You need to hire someone who is an expert with this type of chiller to do the installation.

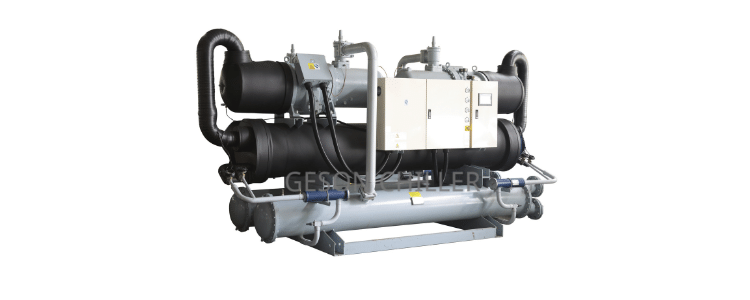

What Types of Screw Chillers?

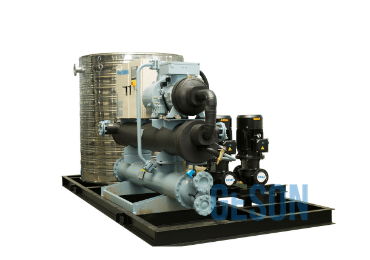

There are two types of screw chillers: air cooled screw chiller and water cooled chillers. In order to understand how this type of chiller works, it is important to look closely into each type.

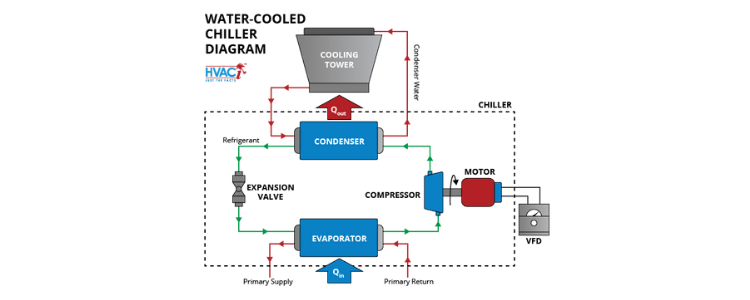

The water cooled screw chiller uses water in order to generate the cooling effect. The screw compressor takes the low temperature refrigerant in the evaporator and directs it into the cylinder until it goes through the compressor steam. The refrigerant passes through the condenser and into the exhaust pipe wherein it exchanges heat with the cooling water. It goes through another process that condenses the refrigerant gas into a high pressure liquid. It goes through several more processes of continuous circulation until the cooling of water is achieved.

How Does It Work?

The next type is the air cooled screw chiller that consists of the semi-hermetic screw type compressor as its primary component. The working principle of this unit starts with the compressor and then moves to the condenser and evaporator before it goes through expansion valve. From there, it enters the dry filter and passes through the pump.

What Are The Different Types of Chillers?

In general, there are two types of chillers available in the market,

The screw type chiller and the piston chiller. These two types of compressors are designed to convert a power source into stored energy consumption through compressed air. Choosing between the rotary screw and piston type compressor will depend on your needs and the purpose for using the system.

What is the Difference Scroll Chiller Vs Screw Chiller:

The Difference Screw Chiller Vs Scroll Chiller.

Using screw compressor, the compressor is at the height of the screw

During the high-speed rotation meshing process, a certain amount of vibration will occur

Movement, noise and with the increase of working hours, caused by

As the rotor gap increases, operating efficiency decreases and power consumption increases.

Using a fully enclosed scroll compressor, the compressor runs smoothly, with low vibration, low noise and long service life.

Screw Vs Scroll Chiller

What is Piston Type Chillers?

The piston type or reciprocating chiller involves the movement of pistons in a downward motion. The up and down motion of bringing gas into the system is the reason why it is called a reciprocating motion. It has plenty of moving parts such as the piston, crankshaft, piston ring, valves, connecting rods, and more. Due to the number of parts, it is very prone to breaking down, especially when one of these parts are not in proper placement or are not functioning properly. This is one of the reasons why many industries have done away with the piston type chiller since it is not very reliable. At the same time, it is also very large in size so you need a separated compressor compartment, which also helps to reduce noise and vibration.

The second type of chiller is known as screw type chiller. It utilizes a rotary compressor, which is also known as a roller. Unlike the piston type chiller, the rollers sit off-center so that one of them comes into contact with the wall. This movement mimics the function of the reciprocating compressor, which allows gas to come in and out. The basic principle of the two moving parts is that they move towards the opposite direction so that air can be drawn in between.

Scroll chillers start at 20 tons and go up to 200 tons in size. It is important to understand that screw chillers only have one compressor used for cooling, so if this goes down then the entire capacity of the chiller would be lost.A screw chiller has excellent full-load and part-load power/ton efficiencies.

What is the difference between screw chiller and centrifugal chiller?

Centrifugal compressors have improved full load efficiency, but screw compressors are not far behind. They’re also comparable in part load efficiency. And in part-load applications, they’re better because they’re stable down to 10% capacity, where centrifugal compressors can start to produce surges at 20% up to 40%.

What Features To Look For in Air Cooled Screw Chiller?

When investing in air cooled screw chiller, there are a few features to look for. The first one is the high-efficiency compressor. This is vital as it ensures stable operation, the efficiency of cooling performance, and the ability to save energy consumption.

Another feature to look for is the frosting method. It optimizes the defrost cycle so as to ensure that the unit can perform optimally at all times. Other features to take into account include the motor cooling unit and the heat exchange tubes. The latter is particularly important because a sealed and reliable tube can increase efficiency by 5%.

Air screw compressor chiller

What Are The Common Uses for Screw Type Chiller?

There are plenty of uses for this type of chiller in today’s society. The first one is for industrial use. It can generate chilled water of up to 5 degrees Celsius. In some cases, it can even produce -5 degrees Celsius so that it can for central air conditioning, ice storage, and other similar production needs in an industrial setting.

What is the Application of the Screw Water Chiller Systems?

This type of chiller is also used widely in the construction industry. One of the most common examples is chilled water for building concrete. The process of concrete cooling is known to have a significant impact on the hardness and the toughness of the concrete material.

Aside from the concrete industry, the use of screw type chiller is also prevalent in food processing. The use of low temperatures for the preservation of food and other perishable goods is important. Therefore, it comes as no surprise why this industry requires the use of chilled equipment. Maintaining the right level of temperature is vital for food storage and preservation.

And of course, the air cooled screw chiller is essential in creating air conditioning units. The HVAC industry relies on this technology in order to provide cooling effect to residential or industrial settings.

These days, there are many industries that use screw compressor chiller. With more industries recognizing the scope of its application and use, you can only expect for it to grow in demand in the years to come.

Industrial Water Chiller Application

What Is The Four Pre-cooling Processes For Poultry Chicken Slaughter?

Poultry chicken slaughter will enter the pre-cooling stage after passing through processes such as stunning, feathering, wax immersion, and evisceration. The main purpose of pre-cooling is to cool the carcass, so as to ensure the quality of the products after processing and leaving the factory. The specific operation is to place the carcass in a low temperature environment of 0~5°C for a period of time to reduce its temperature to below 8°C. At present, the most commonly used pre-cooling methods mainly include air cooling, water cooled, wet cooling and spray cooling.

1 The air cooled Screw Chiller For Chicken Processing type uses air circulation to cool the carcass, which is a more economical pre-cooling method with early investment. The disadvantage is that the gas circulation will not only take away part of the heat, but also take away a lot of water. The carcass is in an air-dried environment, which has a greater impact on the quality of poultry meat.

2 The water cooled Screw Chiller For Chicken Processing type is to put the chicken and poultry body in cold water for cooling, which in a certain sense makes up for the shortcomings of the air cooled screw chiller type. But its disadvantage is that the pre-cooling process consumes a lot of water and is relatively poor in energy consumption saving; the carcass is soaked in water for too long, which will affect the texture and taste of the meat and reduce the quality of the meat.

3 The wet cooled method uses damp and cold air to cool the carcass. This method has a better cooling effect and has little effect on the meat. It is suitable for the cooling process of fresh products, but the initial investment cost is higher.

4 The spray cooling type combines the advantages of air cooling and water cooled. It can maintain the moisture content of the carcass surface in a normal state without affecting the meat. It also has excellent performance in energy consumption saving and consumption reduction, and it can shorten the cooling time. The pre-cooling method is widely used.

Is Screw Chiller More Energy-Efficient?

Yes. Energy saving is one of the known benefits to the use of water cooled screw chiller. The use of a screw compressor unit enables the entire system to maximize power conservation. As a result, it uses less energy to cool a particular space or deliver the cooling effect. It has a high energy efficiency ratio compared to the piston type chiller. It is recommended for those looking for energy-efficient cooling systems.

Is It Suitable For High-Rise Building?

Yes. The reliability of a screw compressor chiller is suitable for the cooling needs of high-rise buildings, whether it is for residential or commercial use. This water cooled system is the choice for modern buildings because of its optimal performance – less maintenance, compact size, and energy-efficiency. The use of pipes for installation means that it does not require a lot of space in order to cool the entire building.

Water Cooled Screw Chiller Room

What Is The Best Chiller Efficiency?

The cost of cooling a building is one of the biggest shares in your utility bills. Therefore, energy efficiency is a priority when it comes to choosing a cooling system. The chiller efficiency can be measured based on the load and the amount of power-saving. If you think about the long-term operation of the chiller, any small savings can add up over time.

How to Choose Screw Water Chiller Supplier?

When looking for a supplier for a screw water chiller, always go for ones with many decades of experience in the industry. If possible, they should supply chillers for both industrial and commercial applications. Take time to do your research on the quality of service they provide. Aside from the quality of the units they can offer, the right supplier must have a good track record in terms of the after-sales service. A good supplier must be able to install and perform maintenance work on the unit, if necessary. Moreover, they should provide detailed instructions or an extensive maintenance guide to ensure that the water cooled screw chiller functions properly at all times.

Screw Chiller for Pharmaceutical Processing

How Do You Ensure Quality?

If you are shopping around for a screw water chiller supplier, there are a few things you need to know. The most common features you need to keep an eye on when doing your comparison include the load cooling capacity rating, coefficiency, refrigerant type, and input power. When determining the screw chiller, the cooling load and intended purpose must be taken into account, as well.

Screw Chiller Working Principle

What is Load Cooling Capacity?

Load cooling capacity is the amount of heat that a chiller can remove from the building’s mechanical room.

How Screw Chillers Improve Capacity

Screw chillers are the most efficient way to chill water in an industrial or commercial setting. They can be used to take the temperature of water down to 4°C (39°F) for cooling purposes. The water is pressurized and forced through a rotating screw inside of a closed chamber where it goes through an evaporative process. This process creates cold temperatures for this process, which in turn produces chilled or cold water.

The deliver optimal efficiency of screw chiller comes from its ability to self-trim when running at high-pressure. When the pressure is high, the amount of heat that is lost will decrease due to reduced friction between the screw and pipe wall when rotating at high speeds.

How the Right Screw Chiller Can Help You Meet Your Thermal Efficiency Goals

It is more important than ever that you are designing your screw chillers for maximum thermal deliver optimal efficiency. Screw chiller manufacturers have done their part by implementing new innovations in their designs to ensure that they are providing the best, most efficient machines possible. But you need to do your part too.

The right screw chiller can help you meet your thermal deliver optimal efficiency goals, but only if it is built to the specifications of the application.

The Advantages of Water Cooled Screw Chillers

The water cooled screw chiller is a sensible choice for low-temperature cooling applications. They are able to provide precise control over the amount of cooling required, and they require less energy to operate than traditional air cooled chillers.

The advantage of these machines is that they use less energy than their traditional counterpart. The water cooled screw chiller offers a more precise level of control over the amount of cooling required, and therefore offers greater flexibility in terms of its operating parameters.

In conclusion, water cooled screw chillers are a sensible choice for low-temperature cooling applications as they offer a more precise level of control over the amount of cooling required and therefore offer greater flexibility in terms of their operating parameters

The Disadvantages of Water Cooling Screw Chillers

Water cooled screw chillers are not good alternatives to air-cooled screw chillers. They are typically more expensive, have a higher installation cost, and have a much greater space requirement.

The water cooled screw chiller starts off with a higher initial cost than an air-cooled screw chiller. The installation costs are also typically much higher because the water cooling system requires more electricity to operate. Finally, the same amount of space is needed for both types of systems because of the size and form factor.

A screw chiller is a form of heat exchanger which is used to heat recover from a process stream and transfer it to a water stream. The water in a modern chiller enters the unit at the inlet and exits it at the outlet. The introduction of screw chillers has made chiller units more efficient, allowing them to produce larger quantities of chilled water with fewer moving parts.

What is the difference between screw chiller and centrifugal chiller?

Centrifugal compressors have improved full load efficiency, but screw compressors are not far behind. They’re also comparable in part load efficiency. And in part-load applications, they’re better because they’re stable down to 10% capacity, where centrifugal compressors can start to produce surges at 20% up to 40%.

Why is it Important to Restore Critical Cooling System Pressure?

If the Restore Critical cooling system pressure is too high, this means that the air conditioner is not able to do its job. The Restore Critical cooling system will keep trying to cool down the room, but it will have a difficult time doing so because the pressure is too high. If you are looking for some tips on how to restore critical cooling system pressure, then continue reading.

This article will cover some of the most common causes of high cooling system pressure and how to fix them. It also provides information on how to avoid getting into these situations in the future.

How Enhanced Refrigerant Management Can Help Reduce Operational Costs

Enhanced refrigerant managementt is designed to reduce operational costs in refrigeration systems by reducing the amount of refrigerant used. Enhanced refrigerant management process includes monitoring system performance to detect when an adjustment in pressure or volume of refrigerant is necessary.

Testing Methods for Screw Chiller Temperature Distribution

The goal of this section is to introduce the reader to screw chiller temperature distribution.

The control system in the chiller is the variable speed drive that provides accurate output with a given input.

The volume ratio in a screw chiller compressor refers to the ability of the screw compressor to move an increased volume of fluid through the same rotational speed. Vriable speed drive means that there are more revolutions per minute in a screw compressor than in a centrifugal compressor for the same horsepower input.

How Do Screw Chillers Differ from Piston Chillers?

There are two main differences between the screw compressor and piston chillers. First off, the screw-type contains only two moving parts while the piston type has plenty of moving parts. The parts on the screw chiller do not come into contact with each other since they move in the opposite direction. Meanwhile, the piston type chiller has parts that come into contact with each other to process gas in a continuous circulation.

Screw Chiller Diagram

What Industries Typically Use Screw Type Chiller?

As mentioned above, there are many applications for the screw chiller. It is mostly used in the HVAC industry to provide lasting solutions to air conditioning needs. It is also widely used in other industries such as the food processing industry, construction industry, and the e-commerce industry, to name a few.