Why Choose Geson Water Chiller Units

A water chiller unit is a device that is developed to remove heat from the water and into a refrigerant following a shut circle framework. Following this process, the refrigerant is siphoned out in order for the heat to be processed further. The cooled liquid is then fed onto the other components to produce a cooling effect for industrial use.

Contrary to popular belief, the use of a water chiller unit is not just limited to HVAC systems, particularly in residential properties. It is just one of its many applications, of which you will know more later on.

Geson chiller focuses on Industrial/Commercial central chiller systems for over 15 years.

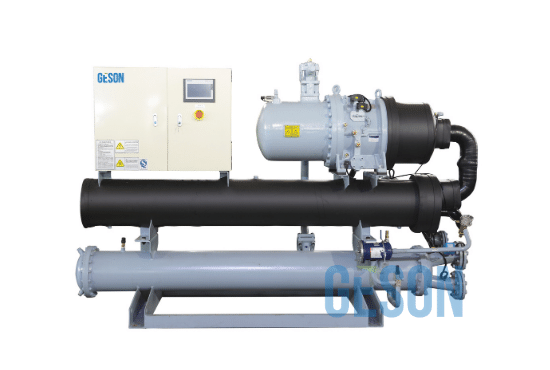

Including Water-cooled chillers, Air-cooled chillers, Screw Chillers, Scroll Chillers, Centrifugal chillers, Water(ground) source heat pumps, Air source heat pumps, and another central chiller system, etc.

Geson water chiller has is widely applied in the Commercial facilities, Pharmaceutical clean room, Chemical industry, Plastic Injection and extruding industry, Artificial Real Ice Rink projects, Environmental simulation laboratory, Computer server room, Telecommunications stations, Food and Beverage processing cooling, Cold storage room, Die casting, Rubber, Printing and many other industries.

Contact our engineer, to get the right central chiller system solution for your industry.

All Types of Industrial Water Chiller Products

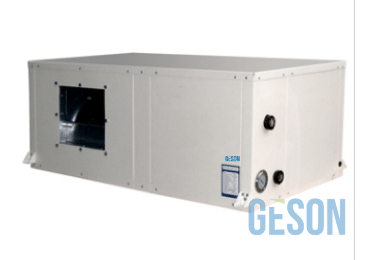

Modular Air Chiller

GESON Water Chiller Unit Manufacturing

|

|

|

|

|

|

Industrial Water Chiller Unit Datasheet |

|

| Model | GS-350WD |

| Cooling Capacity (kW) | 360 |

| Total Power (kW) | 102 |

| Refrigerant | R410A |

| Compressor Type | Semi-closed 5:6 asymmetric twin-screw compressor |

| Leaving Water Temp (℃) | 7 |

| Entering Water Temp (℃) | 12 |

| Shipping Weight (kg) | 2850 |

| Operating Weight (kg) | 3150 |

| Length (mm) | 4600 |

| Width (mm) | 2000 |

| Height (mm) | 2500 |

Applications

Chiller For Plastic Industrial

Beer And Wine Fermentation Chiller

Chemical Processing Chiller

Computer Data Center Chiller

Food And Dairy Chiller

Hotel HVAC Chiller

MRI And Laser Chiller

Pharmaceutical-Formulation-chiller

Swimming-Pool-chiller

Advantages of Geson Chiller

We want to be your expert chiller manufacturer in China

Your Top Quality Chillers Manufacturer In China

Top Brand Components

Ensure Your Top Quality Chiller

Water Cooled Chiller Unit Supplier in China | Geson Chiller

A water chiller unit is a type of liquid cooling device that is designed for industrial purposes. As the name implies, it processes cold water that is responsible for cooling different types of industrial equipment.

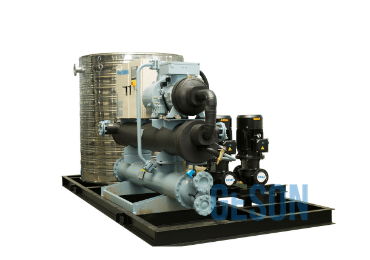

A water chiller unit is not just a unit itself but rather a full system. It is made of different components that make it a complete refrigeration system. Among its parts are the condensers, pipes, cooling pumps, cooling reservoirs, and more.

When the liquid is processed through the water chiller unit, it is able to achieve a certain temperature. Once it has reached the ideal water temperature, the liquid is pumped into a circuit so that it can provide cooling for industrial equipment.

Commercial Water Chiller

The water chiller unit is one of the most simplified systems out there. This is part of the reason why it is popular in numerous industrial applications. The consistency of the water flow and the hydraulic-based circuit ensures there is adequate cooling at all times.

If you are looking to install a Commercial Water Chiller and Industrial Water Chiller Unit, read this guide to help you determine the right fit for your needs. The frequently asked questions will provide the information you need to make the best buying decision.

Figure 1 – Small Water Chiller Unit

What Is A Water Chiller Unit?

A water chiller unit is a device that is developed to remove heat from the water and into a refrigerant following a shut circle framework. Following this process, the refrigerant is siphoned out in order for the heat to be processed further. The cooled liquid is then fed onto the other components to produce a cooling effect for industrial use.

The process of removing heat from the water is essential in order to maintain an ideal temperature. The ideal temperature produced by a water chiller unit is one that can keep the industrial equipment and machinery cool even when they produce heat while in use.

Without a water chiller unit to keep the equipment cool, they are prone to damage. This is because the equipment generates heat while in operation. This is why the use of a water chiller unit to deliver cooling is very essential and one of the best investments for industrial use.

Contrary to popular belief, the use of a water chiller unit is not just limited to HVAC systems, particularly in residential properties. It is just one of its many applications, of which you will know more of later on.

Industrial Water Chiller

What Is A Water Chiller Unit Used For?

The primary function of a water chiller unit is to lower the temperature of industrial or commercial spaces. It employs the use of a refrigerant within a closed loop system in order to facilitate the transfer of heat.

Essentially, the system of eliminating heat is designed to cool a given space or equipment within a manufacturing plant or industrial process. A Portable Water Chillers Industrial is capable of producing low temperatures of up to 4 degrees Celsius (although it varies based on the cooling capacity of the unit).

Portable Water Chillers Industrial

How Much Is A Water Chiller Unit?

The cost of an Industrial Water Chiller Unitunit varies significantly on the brand, size, cooling capacity, and the region where you belong. A water chiller unit is estimated to cost roughly $400 per 400 ton and below. You can expect it to cost more than that if you need a higher cooling capacity.

The price stated above is only an estimate, though. There are several factors that can cause the price to fluctuate. Make sure you consider the reputation and expertise of the manufacturer where you choose to buy the Industrial Water Chiller Unit from to capitalize on your investment.

How Does A Water Chiller Unit Work?

A water chiller unit works with the help of a pumping system. It is responsible for drawing in water from a source and then circulating the cooled water throughout the system. The cool fluid has undergone numerous processes to eliminate heat before the warm fluid goes back to the start of the cycle for it to be processed again.

A chemical compound known as a refrigerant is needed for a water chiller unit to work. There are a variety of refrigerants that are available and each option has its own sets of pros and cons. The basic principle behind this is that the refrigerant goes through a phase change as part of the refrigeration cycle of the water chiller unit.

There are two types of condensers used in a water chiller unit. The air cooled condenser uses ambient air while the water cooled condenser uses water. The latter requires the use of a cooling tower to complete the refrigeration cycle.

Small Water Chiller

What Are The Applications Of A Water Chiller Unit?

There are several applications for a water chiller unit in an industrial setting. This showcases the wide-reaching benefits of this system in maintaining key industrial processes.

It is used in process cooling since industrial equipment and machinery generate heat while in operation. The Industrial Water Chiller Unit is responsible for keeping the area and equipment cooled at all times.

The plastic manufacturing industry is another example of the industrial application of water chiller unit. Plastic is very sensitive to temperature changes. Maintaining a low temperature is essential when undergoing molding to facilitate the injection molding cooler process.

Aside from plastic, the water chiller unit is also used in metal plating processes. The use of high temperature is essential to allow the metal to electrically bond. For this reason, proper cooling is required to compensate for the extreme heat produced during the process.

The list goes on when it comes to the industrial applications of a Water Cooled Chiller System. Other common examples of its use are in the food processing, petrochemical, agriculture, and pharmaceuticals industry.

What Are The Benefits Of Using A Water Chiller Unit?

There are plenty of benefits that you can get with the use of a water chiller unit. The longer life span is one of the main reasons why a Water Cooled Chiller System is used for industrial processes. Therefore, you won’t need to replace them as often as you would with air cooled chillers.

The quiet operation is also a distinct advantage that you can get from a water chiller unit. It does not have ducts and vents like air cooled chillers do. For this reason, you can keep the noise level down while maintaining an ideal low temperature.

In terms of efficiency, the Water Chiller Units Industrial also brings many benefits. It has a CoE that is up to 10 times better than other chiller systems. The water chiller unit is able to transfer heat more effectively, which also means that you can achieve cooling at a faster rate. This could translate to more savings in the long run, as part as operational cost is concerned.

When it comes to the installation of a water chiller unit, it does not require an open space. If you do not have access to that, then installing this type of chiller unit won’t be a problem.

Finally, a water chiller unit is extremely safe to use. Water is the primary choice of coolant so you do not have to rely on toxic chemicals in order to deliver cooling effect.

Water Chiller Unit

Are There Any Disadvantages To A Water Chiller Unit?

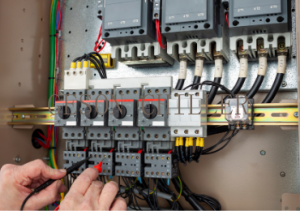

While there are notable advantages to a water chiller unit, there are also a few disadvantages to be aware of. The initial cost of installation is more expensive as compared to air cooled chiller units. You will have to install additional parts such as the water pumps and the cooling towers.

In terms of maintenance, you will have to dedicate more time and effort to care for a Water Chiller Units Industrial. You need to conduct periodic inspections and water treatment. Otherwise, the water could leave behind impurities that can damage the different components of the water chiller unit.

The fact that there are more parts to a water chiller unit also means that the installation is more complicated. You need to hire a professional to perform the installation of the unit.

Figure 5-Cold water chiller units system

What Are The Features Of A Water Chiller Unit?

There are several features that make up a water chiller unit. Each of these features play a significant role in ensuring the function of the entire system and to generate adequate cooling performance.

A water chiller unit comes with a water-cooled condenser that is attached to a cooling tower. It is very common in medium to large installations that have access to a reliable water supply. The water chiller unit types that you will find in the market range in cooling capacity starting at 20 tons and can go up to thousands in tons of capacity.

A recirculating condenser is another common feature found in a water chiller unit. It is mainly responsible for condensing the refrigerant. Since the water chiller unit is not dependent on the ambient temperature, experts believe this type of chiller unit is more reliable and efficient.

Water Cooled Chiller System

Is A Water Chiller Unit Installed Indoors Or Outdoors?

A water chiller unit is usually installed indoors so that it is protected from the harsh environmental factors. This is also part of the reason why a water chiller unit has a longer life span. The added installation of a cooling tower will require an additional expense during the initial setup of the unit.

Do I Need Water Chiller Unit For DWC Systems?

The use of a water chiller unit for DWC systems is important. Otherwise, they heat up really fast when it circulates the nutrient solution. Maintaining proper temperature is very important to facilitate in its processes.

Industrial Water Chiller Unit

What Type Of Pipe Is Used For Water Chiller Unit?

There are two types of materials that are commonly used for piping systems of a water chiller unit: copper and black steel. The use of PVC is not recommended or any other types of plastic material. This is something to consider when choosing a water chiller unit.