Your Best

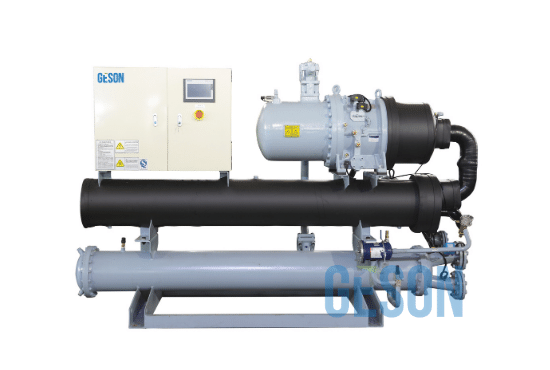

Water Chiller System

Solution and Supplier

Are you Looking for WaterChiller System?

GESON WaterChiller System is One of The Leading Water CooledChiller Systems manufacturers in China.

All Ranges of Water Chiller System and High-Quality Will Give You the Best Solution.

Composition: Compressor, Condenser, Evaporator, Filter Drier, Refrigerant and Throttling Device

Types: Water-cooled Chiller, Piston Compressor Water-cooled Chiller, Air-cooled Chiller, etc.;

Condenser: Shell and Tube Heat Exchanger, Sleeve Type Heat Exchanger, Shell-coil Type Heat Exchanger, Spiral Plate Type Heat Exchanger;

Types of Evaporator: Dry Type, Recirculation Type, and Flooded Type;

Cooling Capacity Ranges: 30 Ton~4500 Ton.

Coolant Temperature: From -140℃ to 30℃

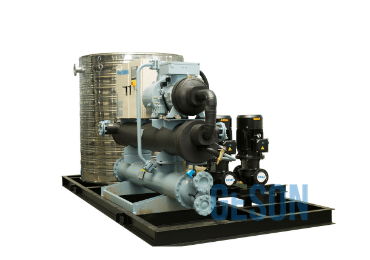

Compressor Energy Efficiency is 20%~30% Higher;

Adopts Famous Bitzer compressor, Hanbell compressor, Fusheng compressor;

Automatic Detection of Cold Water Outlet Temperature and Operating Conditions;

Application Industry: Plastic Processing Industry (Molding Mold Cooling and Injection Molding Cooling, Extruding Machine Cooling), Machine Tool Industry (Hydraulic Media Cooling), Medicine, Chemical Industry, Food Processing Industry, Air Conditioning, and HVAC Industry

Main Products

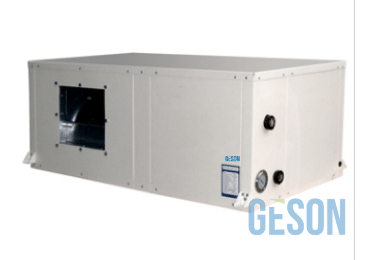

Water Chiller System 12/7℃

- Customize for the Customer’s Requirements;

- One-stop Solution and Service;

- Ranges from 100ton~4400ton Cooling Capacity.

- Ranges from 100TON~4500TONS.

- Famous Leading Screw Compressor Brands;

- Stable Operating Performance;

- 20TR~570TR (70KW~2000KW)

- -5C~20C Chilled water temperature

- Semi-hermetic screw compressor

- SIEMENS PLC controller

- R22/R134A/R407C/R410A options

Related Industrial Water Chiller Products

Your Top Quality Chillers Manufacturer In China

Top Brand Components

Ensure Your Top Quality Chiller

Applications

Chiller For Plastic Industrial

Beer And Wine Fermentation Chiller

Chemical Processing Chiller

Computer Data Center Chiller

Food And Dairy Chiller

Hotel HVAC Chiller

MRI And Laser Chiller

Pharmaceutical-Formulation-chiller

Swimming-Pool-chiller

A water chiller system is one of the most widely used technologies in today’s market. It is crucial in performing a wide range of industrial and commercial processes. Without proper cooling, several industries could suffer and will not be able to survive.

If you are looking for a chiller that is going to facilitate commercial and industrial processes, you have come to the right place. This is a complete guide on water chiller systems and essential information you need to know before you make an investment.

Feel free to browse the frequently asked questions below and their corresponding answers so you can be informed when you need to install this system.

What is a Water Chiller System?

A water chiller system is primarily designed to lower the temperature of the water. It is designed to reject heat from an internal component, environment, or liquid (obviously, since it is a water chiller).

It is a type of refrigeration system that is utilized for a wide range of machinery and uses. This type of refrigeration system is most commonly used in industrial processes.

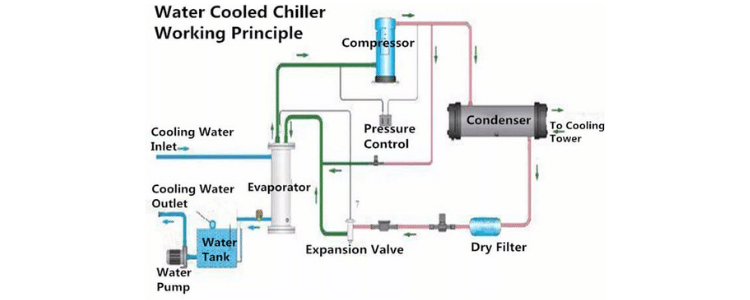

Figure 1 – Water Chiller System

How Does a Water Chiller System Work?

The working principle of a water chiller system is quite complex. There are several parts involved that must work together to ensure that any excess heat from the water is eliminated in order to facilitate the cooling process.

The heat-transfer activity involves the evaporation of a refrigerant. It transforms the low-pressure liquid into vapor form in order to facilitate a drop in the temperature of the liquid coolant. From there, the refrigerant is fed onto a compressor wherein it performs a variety of functions.

How Does A Water Chiller System Work

What Are The Three Basic Types of Water Chiller System?

There are plenty of categories used to describe different types of water chiller systems. They can be recognized into three basic types: 1) air-cooled chiller system, 2) water cooled water chiller system, and 3) evaporative condensed chiller.

There are many other sub-categories based on the compression technology used. Make sure to invest time to get familiar with these different chiller systems so you can choose the most appropriate type of chiller to use for your desired application.

Air Cooled Water Chiller System

What is a Closed-Loop Water Chiller System?

A closed-loop water chiller system is called such because it is a recirculating system. It utilizes a coolant liquid that is contained within a closed-loop setup. The exchange of heat takes place within this closed loop to generate cooling for industrial and commercial applications.

There are two types of refrigerants commonly used in a closed-loop water chiller system: water-based coolants and oil-based coolants.

The coolant is introduced into a coolant tank before it is repeatedly passed onto a heat load. This is where any excess heat is absorbed to reduce the temperature of the water enough to suit industrial and commercial needs.

The heat that is absorbed from the coolant is fed into an evaporator before it is fed back to the coolant tank. This is where the cooling process chiller takes place and then the process starts all over again.

A thermostat is responsible for regulating the temperature of the refrigerant. It is capable of automatically detecting changes in temperature in the coolant tank. It is then responsible for adjusting the refrigeration effect in the evaporator to achieve the optimal temperature.

What Are The Benefits of a Closed Loop Water Chiller System?

There are plenty of benefits to choosing a closed-loop system for your water chiller. First and foremost, it is a practical choice because this is one of the most cost-efficient water chiller systems in the market.

It is also an environmentally-friendly option. It is more efficient than a single pass cooling setup because the water is dump right after. With a closed-loop system, the water is recycled as it is used repeatedly in a closed-loop setup.

Cheap Water Chiller

Aside from this, a closed-loop system also reduces the amount of water needed for cooling. Therefore, you are using less amount of water in general. It also involves lower sewage costs because you are not dumping as much water as with a single pass system.

The lack of constant dumping of used water also means that you are not releasing contaminants into the bodies of water, which can harm aquatic life. This is why it is recommended as a more eco-friendly option.

If you plan on expanding your water chiller system in the future, this system makes it easy to make adjustments over time. You are free to add to the system as your needs expand.

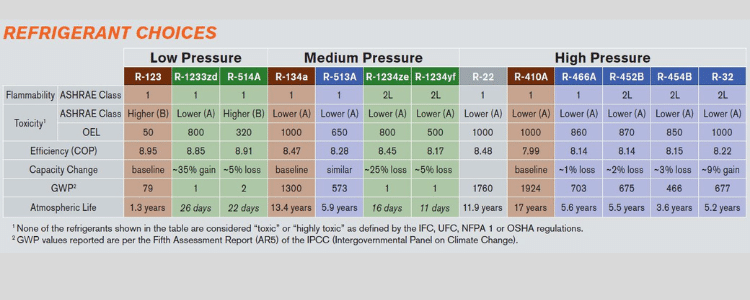

Refrigerant Is Used In a Water Cooled Chiller System

Where Do You Use a Water Chiller System?

There are many applications for a water chiller system. It is most commonly used for industrial water chiller applications. However, the most prevalent use of this refrigeration system is in hospitals, restaurants, manufacturing plants, and other commercial HVAC chiller spaces.

Water Chiller System For Home

What Are The Categories of the Water Chiller System?

There are two general categories of water chiller system that is used in the market: vapor absorption and vapor compression. As you can see, the type of water chiller system is based on the technology used to operate them.

Of the two types of water chiller systems, vapor compression chillers are most commonly used. It has its own sub-categories: air and water chiller system.

On the other hand, there is also another distinction for vapor compression chillers based on the type of compressor used. You can choose from scroll chillers, reciprocating, centrifugal, and screw chillers.

These different categories of water chiller systems differ in terms of how they operate and the technology used. It is important to take note of these differences as they can impact how the system operates and its corresponding maintenance requirement.

Water Screw Chiller

Can You Use Water Chiller System for Centralized Cooling?

Yes. A water chiller system is mainly used for centralized cooling solutions that keep a building or several buildings cool. You can also find smaller systems that are designed for cooling a single location. This eliminates the need to install several types of equipment in various places.

This approach for installing a water chiller system is a practical solution because it makes it easier to maintain the water chiller units later.

Chiller System Diagram

Is a Water Chiller System More Efficient?

Efficiency is a critical factor to consider when investing in a water chiller system for industrial or commercial use. If you choose a water chiller, you’re in luck because this is known for its higher energy efficiency.

A chilled water system offers higher energy efficiency as compared to installing smaller, individual systems. The initial investment of a water chiller system is higher but this initial cost will pay off in the long run as you can save money on your energy consumption.

Aside from being energy-efficient, a water chiller system is also the best solution for large-scale cooling such as in industrial and commercial spaces. This is especially a good investment in buildings wherein installing refrigerant through the pipes is not allowed for various reasons.

Water Cooled Chiller System Design

Is a Water Chiller System More Versatile?

Flexibility is one of the crucial advantages of installing a water-cooled chiller. Depending on the type of chiller you choose, there are many configurations from which you can choose. You can install them in an indoor or outdoor space or you can choose from a wide range of compressors.

You can also choose from different types of refrigerants and you can pick one that is eco-friendly. Make sure you shop around the market in order to find customizable solutions to meet your unique needs.

Water Cooled Chiller System Diagram

Is Water Chiller System Suitable for Large Buildings?

Yes and no. A water chiller system can be used to cool a large building with multiple floors. However, it can also be used for smaller to medium-sized buildings.

When shopping around for this system, you can find a wide range of options. Make sure you calculate the total space that you need to be cooled and the specific processes that require cooling. Sizing the chiller system to suit your needs is crucial in order to maximize the energy efficiency and cost-effectiveness of the system.

Water Chiller System Hydroponics

What is the Difference Between Central and Portable Chiller Systems?

When shopping for a water chiller system, there are two general configurations that you will likely encounter: central and portable units. There is a significant difference with these types of systems so make sure you choose accordingly.

Closed Loop Water Chiller System

A portable chiller system is designed to be moved to a different location depending on the process applications required. It also comes with an internal reservoir and pumping system so you can operate the system where you need it.

Most portable chiller systems have capacities ranging from ¼ to 40 tons. It is also capable of supplying process fluid averaging -6 to 20 degrees Celsius.

For central chiller systems, it is designed to support industrial process cooling requirements. It is suited for large-scale applications or cooling needs. Unlike portable units, it is a stationary system.

A central water chiller system is capable of supplying cooling of -6 to 20 degrees Celsius to several use points. It is recommended for large buildings so that there is no need to install multiple units for individual locations.

Small Water Chiller System

How to Optimize Efficiency of Water Chiller System?

Optimization of a water chiller system is an important goal for industrial building owners. The reason for this is that they tend to cover a significant portion of a building’s energy usage. If you invest in an energy-efficient system, then you can significantly lower your energy cost.

The performance of a water chiller system is an important system if you wish to lower the operational cost in your building. There is a complex task involved with optimizing the performance of a water chiller plant.

It starts with gathering data about the current energy performance of the system. It will also involve calculations that will help determine the best way to operate chiller equipment by utilizing as little energy as possible.

schematic diagram water cooled chiller system

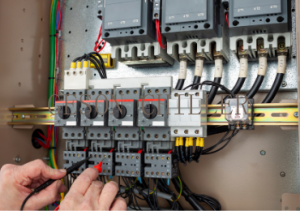

How to Choose Supplier of Water Chiller System?

A water chiller system plays a vital role in ensuring the efficiency of the performance of various industrial cooling processes. Make sure that you choose a supplier that can provide you with a variety of options in terms of the size of the chiller system and its configuration.

This will ensure that you can get the best fit according to your needs so you can keep your operational costs at a minimum. Make sure you also have adequate support from the water chiller system provider. They should be available if you require troubleshooting help.

Portable Water Chiller System

You should also select a supplier that has been in the business for a long time. Their years of experience in the industry are a reflection of their ability to provide solutions that meet their client’s needs.

Moreover, look for a supplier that has a good feedback from its previous clients. You need to specifically look into the feedback on customer service and the team’s responsiveness.