Your Best

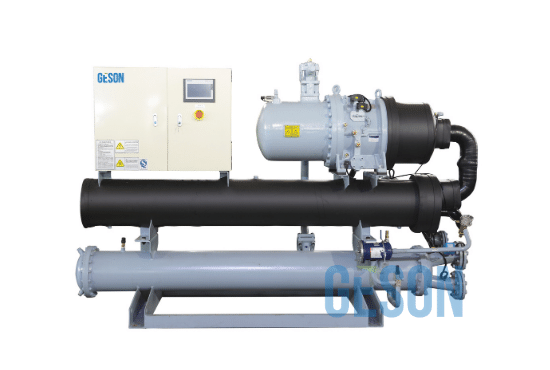

Water Cooled Chiller System

Solution and Supplier

Are you Looking for Water Cooled Chiller System?

GESON Water Cooled Chiller System is One of The Leading Water Chiller Manufacturer in China.

All Ranges of Water Chiller Plants System and High-Quality Will Give You the Best Solution.

Composition: Compressor, Condenser, Evaporator, Filter Drier, Refrigerant and Throttling Device

Types of chillers: Rotary Compressor Water-cooled Chiller, Piston Compressor Water-cooled Chiller, Scroll Compressor Water-cooled Chiller, Screw Compressor Water-cooled Chiller, Centrifugal Compressor Water-cooled Chiller Plants, etc.;

Condenser: Shell and Tube Heat Exchanger, Sleeve Type Heat Exchanger, Shell-coil Type Heat Exchanger, Spiral Plate Type Heat Exchanger;

Types of Evaporator: Dry Type, Recirculation Type, and Flooded Type;

Cooling Capacity Ranges: 30 Ton~4500 Ton.

Coolant Temperature: From -140℃ to 30℃

Compressor Energy Efficiency is 20%~30% Higher;

Adopts Famous Bitzer compressor, Hanbell compressor, Fusheng compressor;

Automatic Detection of Cold Water Outlet Temperature and Operating Conditions;

Application Industry: Plastic Processing Industry (Molding Mold Cooling and Injection Molding Cooling, Extruding Machine Cooling), Machine Tool Industry (Hydraulic Media Cooling), Medicine, Chemical Industry, Food Processing Industry, Air Conditioning, and HVAC Industry

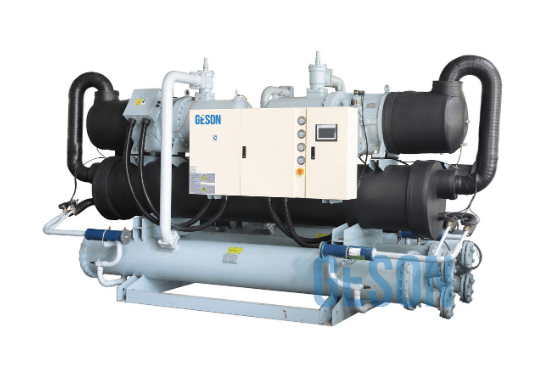

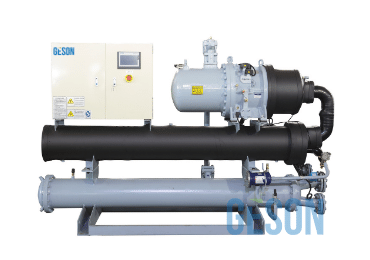

Water-cooled Chiller System Products

Water Cooled Chiller System 12/7℃

Customize for the Customer’s Requirements;

One-stop Solution and Service;

Ranges from 100ton~4400ton Cooling Capacity.

- Ranges from 100TON~4500TONS.

- Famous Leading Screw Compressor Brands;

- Stable Operating Performance;

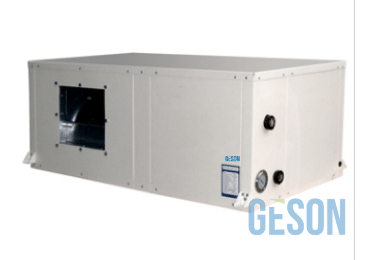

- Ranges from 3Ton~180Ton;

- Famous Leading Scroll Compressors;

- Built-in Water Tanks and Water Pumps.

| Model | Water-cooled Screw Chiller l00WS | Water-cooled Screw Chiller 135WS | Water-cooled Screw Chiller 180WS | Water-cooled Screw Chiller 195WS | Water-cooled Screw Chiller 235WS | Water-cooled Screw Chiller 260WS | Water-cooled Screw Chiller 305WS | Water-cooled Screw Chiller 320WS | Water-cooled Screw Chiller350WS | Water-cooled Screw Chiller 385WS | ||

| Cooling Capacity | KW | 100 | 135 | 180 | 195 | 235 | 260 | 305 | 320 | 350 | 385 | |

| 10′ Kc a 1 / h | 8. 6 | 11. 6 | 15. 5 | 16 . 8 | 20. 3 | 22. 4 | 26. 3 | 27. 6 | 30, 2 | 33. 2 | ||

| Control | PLC Programmable Controller | |||||||||||

| Power Supply | 380V/ 3N / 50H z | |||||||||||

| Compressor | Type | 5- 6 Asymmetric Semi-hermetic Twin Screw Compressor | ||||||||||

| 1 | ||||||||||||

| Starting | Y – △ Starting | |||||||||||

| Running Loading | 0- 33- 66- 100% | 0- 25%- 5 0%- 75%- 100 % | ||||||||||

| Evaporator | Type | Horizontal Shell and Tube Dry Evaporator | ||||||||||

| Pipe Diameter | DN | DN65 | DN80 | DN100 | DN125 | |||||||

| Pressure Drop | kPa | 48 | 48 | 50 | 50 | 50 | 52 | 54 | 55 | 55 | 58 | |

| Condenser | Type | Horizontal Shell and Tube Dry Evaporator | ||||||||||

| Pipe Diameter | DN | DN65 | DN80 | DN100 | DN125 | |||||||

| Pressure Drop | kPa | 46 | 46 | 47 | 47 | 48 | 49 | 51 | 53 | 53 | 56 | |

| Refrigerant | Type | R407C,R134A,R410A | ||||||||||

| Refrigerant Charge | kg | 20 | 27 | 36 | 39 | 47 | 52 | 61 | 64 | 70 | 77 | |

| Diament | Length | mm | 2100 | 2360 | 2450 | 2860 | 2860 | 2860 | 2860 | 2860 | 2860 | 3225 |

| Width | mm | 700 | 700 | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 | |

| Height | mm | 1410 | 1520 | 1580 | 1600 | 1720 | 1745 | 1745 | 1770 | 1880 | 1960 | |

| Weight | kg | 850 | 1050 | 1270 | 1340 | 1640 | 1680 | 1720 | 1750 | 2080 | 2300 | |

| Running Weight | kg | 900 | 1150 | 1420 | 1540 | 1890 | 1940 | 1990 | 2050 | 2330 | 2550 | |

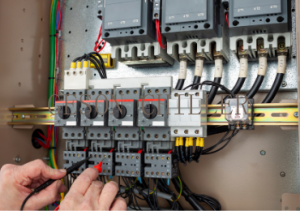

Top Brand Components

Ensure Your Top Quality Chiller

Applications

Chiller For Plastic Industrial

Beer And Wine Fermentation Chiller

Chemical Processing Chiller

Computer Data Center Chiller

Food And Dairy Chiller

Hotel HVAC Chiller

MRI And Laser Chiller

Pharmaceutical-Formulation-chiller

Swimming-Pool-chiller

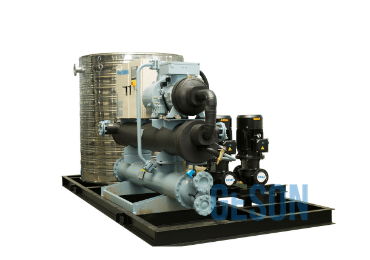

Related Industrial Water Cooled Chiller Products

Why Choose Geson Water Cooled Chiller System?

Are you looking for a professional Water Cooled Chillers Systems manufacturer?

Geson chiller focuses on Industrial Chiller /Commercial Water Chiller Systems over 15 years.

Including full types of Chillers refrigeration System, Air-cooled chillers, Screw Chillers, Water(ground) source heat pumps, Air source heat

pumps, HVAC Chiller, Chiller Plant and etc.

You can get the water chiller refrigeration system capacity from 3 Ton~4500 Ton, and temperature from -145℃~25℃.

Geson water chiller refrigeration system has been widely applied in the industry and Commercial facilities. Pharmaceutical, Chemical industry, Plastic Injection and extruding machinery, Artificial Real Ice Rink projects, Computer data center room, Food, and Beverage process cooling, Cold storage room, MRI and Laser machine, Rubber, Printing, and many other industries. Or large shopping malls, hotels, factories, hospitals, and other central air-conditioning projects.

Geson water chillers have been exported to the Americas, Europe, Middle East, Africa, Southeast Asia, and was praised by customers all over the world.

We will offer one-stop water cooled chiller solutions with the highest reliable quality products and service.

If you have more questions on chiller units, free to contact us.

Your Top Quality Chillers Manufacturer In China

Ultimate FAQ: Water Cooled Chiller System Manufacturers in China | GesonChiller

A water cooled chiller system is one of several types of chillers that have numerous applications in various industries. Find out more about its uses and other information you need to know about operating the system with this list of frequently asked questions.

A water chiller is normally intended for chillers use as an indoor installation.

It is made up of water-cooled condenser and a cooling tower.

Since it processes water source to produce a cooling effect, it is more stable in performance than other types of the chiller.

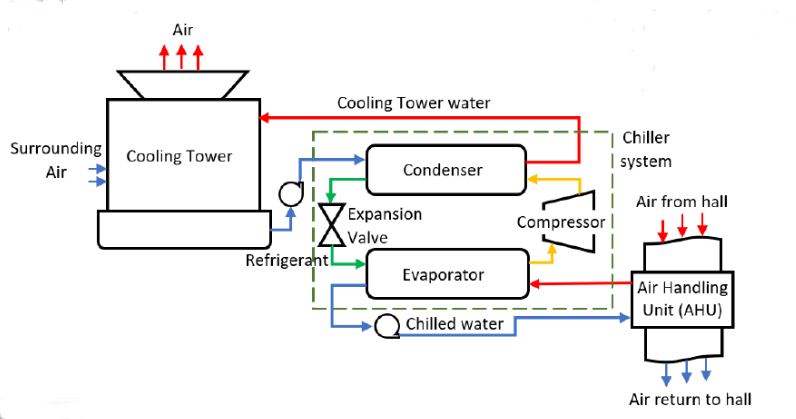

Figure 1: Water Cooled Chiller System

How Water Cooled Chiller Works?

This system involves two steps to perform the heat transfer. The first step is when introduce heat which coming from the refrigerant vapor into the condenser water. After that, introduce the warm condenser water into a cooling tower wherein disperse heating into the atmosphere. This leaves you with the cool water that provides a cooling effect to a particular space.

Water Cooled Chiller Diagram

What Type of Water for The System?

There are many possible sources for water in this system. In most cases, cold water is readily available, especially when install the system near a body of water. Use this water source directly in order to supply the system with the water it needs to function.

In other parts of the world, also use a deep water source for the cooling system. Other systems use cold lake water, whenever available, which is the case with cold climate areas.

Should You Choose Water Or Air Cooled Chillers System?

There are a few differences between a water cooled and air cooled chillers that would differentiate them from each other. Air chiller generates a cooling effect from the ambient air. On the other hand, water chiller generates it from a water source that is cooled in the process.

Air Cooled Chillers vs Water Cooled Chiller

Recommend a water chiller for cooling medium to largea installations. It is also a good option when there is a sufficient water supply nearby. This system is preferr in most cases because it is not dependent on the fluctuations of the ambient air in the immediate environment. However, if the lack of water supply is an issue, then chillers air cooled chillers is the best option.

Chiller System Diagram

Which Refrigerant Is Used In a Water Cooled Chiller System?

There are many types of refrigerants commonly for chiller systems. In the case of cooled chiller, obviously, water is the refrigerant. This comes as a result of the desire to transform this system into a more eco-friendly and sustainable one. The only downside to this type of refrigerant is that it is vulnerable to changes in temperature and can cause corrosion to the components.

Refrigerant Is Used In a Water Cooled System

When Should You Use a Water Cooled Chiller Sytems?

A chiller is the best option to cool buildings or any space that require a centralized cooling system. This system is capable of providing centralized cooling, which is more practical compared to installing several smaller cooling equipment.

What Is The Difference Between Air and Water Chiller Sytems?

There are two primary differences between the air and water cooled chiller. The first major difference is in the source of refrigerant. While chiller uses a water source to provide a cooling effect, the air-cooled chiller draws ambient air in that is then processed by the system.

Air Cooled Chiller Diagram

The second main difference between the two is in terms of the application. An chillers air cooled chillers is suited for smaller installations whereas the water cooled system can be for cooling medium to large scale applications. The third is commonly for cooling buildings and large spaces because it has more cooling capacity.

Figure 2: Water Cooled Chiller