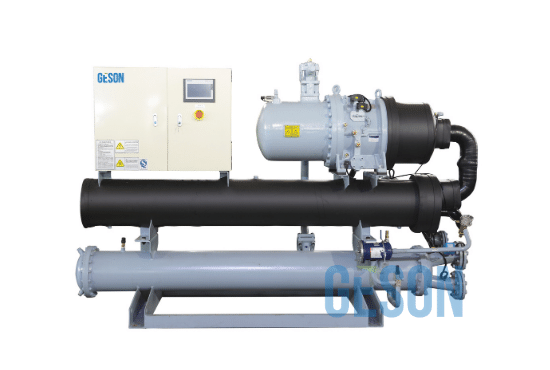

Geson industrial water chillers unit is a perfect choice in the humid and dusty environment area.

Adopts the best suitable compressor, according to the project site need.

Customize the cooling capacity, chilled water temperature, refrigerant types, and voltage type.

You can make your industry at a stable working and lowest cost.

- Chilled water temperature 5~25℃

- Refrigerant types: R22/R134A/R407C/R410A and etc.

- Compact in structure, cover small area, save machine room space.

- Cooling capacity ranges: 30~4500RT

- Loading adjusted 100%, 75%, 50%, 25%,0.

- Completely running tested before the delivery from the factory.

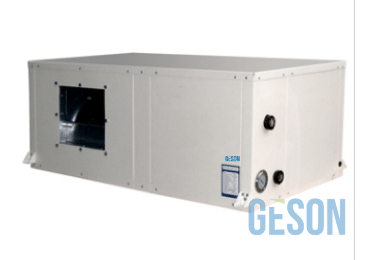

- Cooling capacity ranges: 10HP~80HP

- Built-in a cooling water tank and chilled water tank

- Easy for maintenance and service.

- The scroll compressor is long-life operating and easy to maintain.

Who We Are?

Are you on the lookout for a good and reliable water-cooled chiller unit manufacturer that ships premium units around the world? Geson Chiller unit has a long history of delivering high-quality and reliable industrial chillers packages for a variety of industrial and commercial applications.

Geson includes different types of water-cooled chiller units that can be widely applied to industrial and commercial HVAC systems. Together with our skilled professionals, we ensure you get the best and reliable design that meets your particular needs.

Operating with Geson allows you to benefit from our vast experience procured from hundreds of installations in all types of conditions all over the world.

Reach to us for further assistance.

All Types of Industrial Water Chiller Units

Your Top Quality Chillers Manufacturer In China

Advantages of Geson Chiller

We want to be your expert chiller manufacturer in China

Top Brand Components

Ensure Your Top Quality Chiller

Applications

Chiller For Plastic Industrial

Beer And Wine Fermentation Chiller

Chemical Processing Chiller

Computer Data Center Chiller

Food And Dairy Chiller

Hotel HVAC Chiller

MRI And Laser Chiller

Pharmaceutical-Formulation-chiller

Swimming-Pool-chiller

Chiller Unit: The Ultimate FAQ Guide

This product guide will answer all your queries regarding Chiller Units. Whether it is design, benefits, cost, manufacturer, or any other critical aspect, this article will help you to choose the best chiller available.

If you are concerned about what type of chiller to buy and what fits your needs, this post will guide you through all of it. So, here is a comprehensive guide that you must read.

What Is A Chiller Unit?

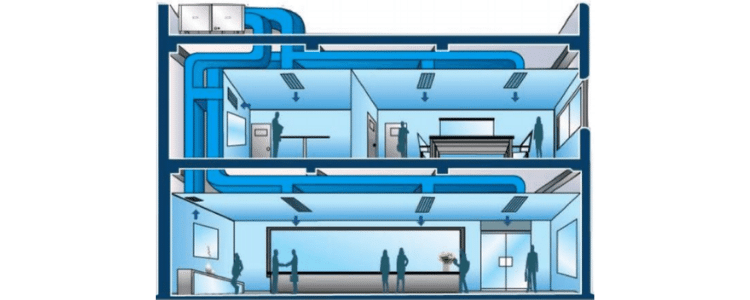

The Chiller Unit generates chilled water used to provide air conditioning in buildings.

It removes the facility’s unwanted heat to keep the people inside at a comfortable temperature and to make sure electrical and mechanical equipment is kept within thermal limits.

Chillers are normally located in the basement or on the roof.

Rooftop chillers are air-cooled whereas basement chillers are water-cooled.

water cooled chillers

How Does A Chiller Unit Work?

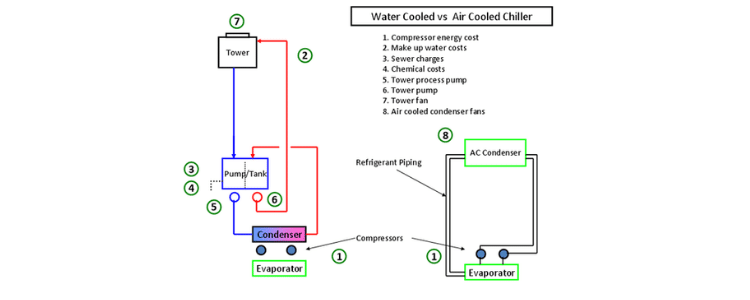

Figure 1 How Does A Chiller Unit Work

The water-cooled chiller uses cooling towers while the air cooled chillers blows air across the condenser, much like an A/C unit, to disseminate the unwanted heat into the atmosphere.

Generated chilled water is sent throughout the building to collect the unwanted heat and bring it back to the evaporator to be cooled down.

The refrigerant collects the heat and moves it to the condenser.

van chiller unit

The condenser will put the unwanted heat into the cooling towers via a chilled water pump to send it in to the atmosphere or send it to a cooling coil where a fan blows the heat away.

portable chiller unit

What Are The Types Of Chiller Unit?

Generally, the two basic types of chillers are water-cooled chillers and air cooled chillers.

Both water-cooled and air cooled chillers are suitable for small-scale and commercial-scale cooling.

The components of both air cooled chilles and water-cooled chillers are mostly the same.

Their main difference is how the refrigerant is being cooled.

What Is The Most Efficient Type Of Chiller Unit?

Water-cooled chillers are generally more efficient than air cooled chillers.

They have a quieter operation than air-cooled systems.

They are suitable for both small-scale and commercial-scale cooling.

Portable solutions are available for facilities with space constraints.

Air Cooled Chillers vs Water Cooled Chiller

What Are The Advantages And Disadvantages Of A Water-cooled Chiller Unit?

Advantages:

- Water-cooled chillers usually don’t need replacement as often as air-cooled chillers do.

- They are not exposed to outdoor elements such as rain, snow, ice, and heat, which makes them less vulnerable.

- Water-cooled chillers transfer heat more efficiently.

- Water-cooled chillers use chilled water as a refrigerant instead of toxic chemicals, making them safer for people who have contact with them.

beer chiller unit

Disadvantages:

- Water-cooled chillers usually have higher costs because they require more parts like cooling towers and condenser water pumps.

- Water-cooled chillers require more maintenance as they have more parts, which means they are more likely to require repairs than air-cooled chillers.

- Since water-cooled chillers use a good amount of water, they aren’t great in regions that have water shortages.

- Although water-cooled chillers are overall more efficient than air-cooled chillers, they will operate less efficiently in humid environments.

water chiller unit

What Are The Advantages And Disadvantages Of An Air-cooled Chiller Unit?

Figure 3 Air-cooled Chiller Unit

Advantages:

- Air-cooled chillers are cheaper than water-cooled chillers.

- They don’t require much maintenance as water-cooled chillers do.

- Unlike water-cooled chillers, air-cooled chillers don’t have extra parts that can make installation more of a hassle.

- Businesses need not have a mechanical room to house an air-cooled chiller as it can be placed at the top of the building.

small chiller unit

Disadvantages:

- Air-cooled chillers are not suitable for companies that don’t have access to enough outdoor space.

- Air-cooled chillers have ducts and vents that create noise.

- They are exposed to outdoor elements such as rain, snow, ice, and heat, which affect the chiller’s lifespan.

- Air-cooled chillers need a replacement more often than water-cooled chillers as they are more exposed outdoors.

air cooled chillers unit

What Is The Ideal Temperature For Your Needs?

In the beer and wine industries, cold temperatures can help with the fermentation process and with keeping the beverages fresher for a longer time.

Food and dairy industries use chillers to cool water for processing, preserving milk, and other easily spoiled products and keep them cooler after harvesting.

Medical researchers use chillers to maintain consistent, low temperatures during experiments.

In data centers, Chillers maintain expensive servers and other computer equipment cooled, keeping them always at peak performance.

Chiller Temperature Setting

What Are The Two Main Categories Of A Chiller Unit?

Chillers fall under two main categories: vapor compression and vapor absorption chillers.

Vapor compression chillers use an electrically driven mechanical compressor to force a refrigerant around the system.

It uses heat to move the refrigerant around the system.

Vapor compression chillers are the most commonly used and fit into two subcategories: air-cooled chillers and water-cooled chillers.

Modular Air Chiller

What Are The Components Of A Water-cooled Chiller & Air-cooled Chiller?

Figure 4 Components Of Chiller

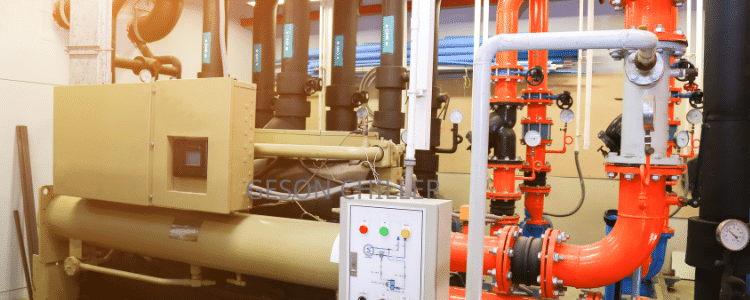

Water-cooled chillers and air-cooled chillers are refrigeration systems used to cool fluids or dehumidify ambient air in both commercial and industrial facilities.

The components of water-cooled chillers and air-cooled chillers are very similar.

Each product contains an evaporator, condenser, compressor, and expansion valve.

The primary difference is whether air or water is used to provide the condenser cooling.

What Is The Use Of Evaporator In The Chiller Unit?

Figure 5 Evaporator on a chiller

The evaporator functions as a heat exchanger.

Captured heat transfers to the refrigerant.

As the heat transfer takes place, the refrigerant evaporates.

The low-pressure liquid will turn into vapor while the temperature of the process coolant reduces.

What Is The Use Of Condenser In The Chiller Unit?

Figure 6 Water-cooled chiller condenser

The condenser is located between the compressor and the expansion valve.

The condenser usually isn’t insulated.

The high-pressure refrigerant vapor enters the condenser and the liquid refrigerant exits the condenser.

The condenser collects all the unwanted heat from the building and transfers them over into the condenser water loop where it will be rejected from the building via the cooling towers.

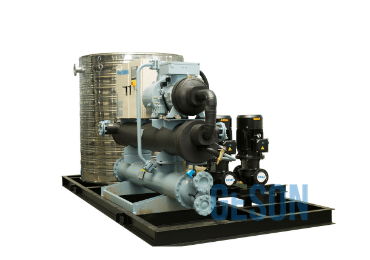

What are Cooling Towers and Chiller Units And How Do They Work?

Cooling towers are used in the water-cooled cycle of the refrigeration cycle. They are used to lower the temperature of the water before it is fed into a chiller unit.

There are 2 types of cooling towers – evaporative cooling tower and air-cooled tower. While evaporative cooling tower uses evaporation to cool down water, air-cooled cooling tower uses ambient air instead.

What are Industrial Chillers Unit?

Industrial chillers are typically large, cylindrical containers that use a cooling system to keep food and other necessary items at a certain temperature.

Industrial chillers come in three types: air-cooled Industrial chillers, water-cooled Industrial chillers and electric-cooled Industrial chillers.

An air cooled chiller is any type of chiller unit that uses air as its cooling agent. Air cooled chilling systems tend to be less expensive than the other two options, but they also tend to be less efficient and require more maintenance. Air cooled chillers can be categorized into two main types: 1) shell and tube; 2) rotary vane type.

A water cooled chiller is any type of chiller unit that uses process water as its cooling agent.

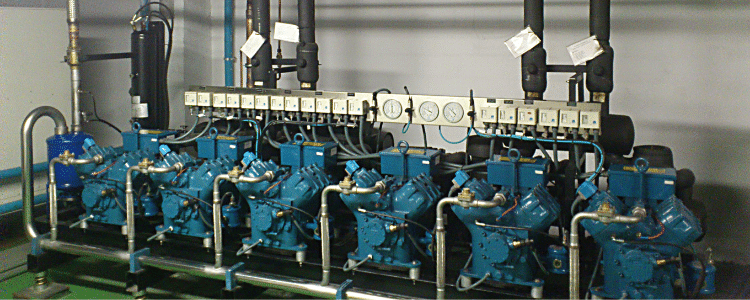

What Is The Use Of Compressors In The Chiller Unit?

Figure7 Centrifugal type compressor

Figure 9 Scroll type compressor

The compressor removes the heat from indoor spaces or from industrial processes.

Once the refrigerant in a chiller absorbs the heat, it becomes a gas.

After the compressor raises the pressure and temperature of the gasified refrigerant, the heat can be expelled.

Air-cooled chillers release heat directly outdoors, while water-cooled chillers release it into a stream of water that is then pumped to a cooling tower.

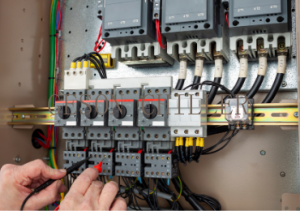

What Are The Basic Steps For Optimized Performance?

Inspect the chiller quarterly and routinely check for refrigerant leaks.

Confirm compressor operating pressures are within a reasonable range and check all motor voltages & amps.

Check all electrical starters, contactors, and relays and check all hot gas and unloader operations.

To reach maximum efficiency, use superheat and subcooling temperature readings, and line readings from Discharge lines should also be obtained.

what is a chiller

What Is The Daily Maintenance Checklist For Chillers?

Turn off or sequence unnecessary chillers.

Complete overall visual inspection to be sure all equipment is operating.

Always ensure that safety systems are in place.

Check all setpoints for proper setting and function.

What Is The Monthly Maintenance Checklist For Chillers?

Assess evaporator and condenser coil fouling as required.

Check temperature per manufacturer’s specifications.

Conduct leak testing on all compressor fittings, oil pump joints and fittings, and relief valves.

Check insulation for condition and appropriateness and verify proper control function including Hot gas bypass and Liquid injection mold cool.

What Is The Annual Maintenance Checklist For Chillers?

Check all seals and provide lubrication where necessary.

Conduct analysis on oil & change as necessary.

Check all electrical connections and terminals for contact and tightness.

Assess proper water flow in evaporator and condenser, record amounts, and address leakage issues.

chiller unit working

What is a Chiller Unit?

Chillers are giant air conditioning. They can provide cooling to larger areas. For centralized air-cooling, they are preferable because of better efficiency than a regular air conditioning.

What is a Chiller Purge Unit?

When the chiller sucks up air from the surroundings, it also sucks incondensable impurities. So, a purge unit separates these impurities from the refrigeration mechanism.

The Complete Guide to Manage Air Conditioning or Chiller Units Smartly

Introduction: What is the Difference Between an Air Conditioning and a Chiller Unit?

Air conditioning units and chiller units are both important components of a commercial refrigeration system. They both work to cool a building’s interior, but they do so in different ways.

In an air conditioning, airflow moves through coils of metal or plastic tubing called an evaporator. The outside of the coils is cooled by the surrounding air, and the cold liquid inside the coils releases heat to the surrounding air as it vaporizes. This creates cooler indoor air than what is found in the climate outside.

A chiller unit works in a very different way than an air conditioning conditioner to pull in heat from indoor areas and release it outdoors via pipes carrying liquid refrigerant under pressure. A chiller unit produces cold water vapor which ultimately cools down equipment inside the building through condensation on surfaces like pipes and walls.

What is TR in the Chiller Unit?

TR is known as Ton Refrigeration. If you have seen TOR, RT, or TR, they all mean the same thing. It indicates the ability of the chiller to extract heat for refrigeration. One TR equals 3.5 kW or 12,000 BTU/h.

What is the Working of the Chiller Unit?

A chiller unit uses some condensation material to pass through the condenser to provide cooling.

What Does a Chiller Unit Do?

A chiller unit provides cooling. They use air, water, or evaporation. Firstly, it depends upon the type of building and technology whether you need an air chiller, a water chiller, or an evaporative chiller.

How Many Types of Chillers Are There?

There are three types of chillers, i.e., Air Chillers, Water Chillers, and Evaporative chillers. Moreover, there are further subtypes for each.

What Are Air Chillers?

An Air chiller unit makes use of ambient air for condensation. There is a fan that moves the air through the condensing coil. These are also called air cooling chillers unit. Also, an air-cooled chiller unit doesn’t need any cooling tower, so their installation and maintenance are more convenient because of water cooling tower.

chiller package unit

What is an Air Chiller Capacity?

An Air chiller unit can start from a basic air conditioning chiller unit to more than a hundred-ton capacity. So, the more massive models are used to cool commercial buildings.

What is a Water Chiller Unit?

A water chiller unit uses water for condensation. The water is driven through with the help of a pump.

Then. the water circulates through the condenser toward the cooling tower. Unlike an air chiller, a chilled water unit requires a cooling tower.

The Difference Between Air Cooled Condensers and Chiller Unit

An air cooled condenser is a type of heat exchanger. Air cooled condensers are commonly used in industrial processes because they can withstand higher temperatures than water-cooled condensers.

An air cooled condenser is different from a chiller unit. A chiller unit usually cools/refreshes the refrigerant before it enters the compressor to make it more efficient. It also reduces the risk of freezing of water-cooled pipes. These units are often used in high-temperature industrial processes to produce chilled water for cooling buildings or machinery, or hot water for heating buildings or machinery.

Air cooled condensers are typically located outside, whereas chillers can be located anywhere, especially indoors where they provide better control over temperature and humidity levels.

What is Chiller Systems and Why is it Important?

A chiller systems is a mechanical device used to cool and dehumidify the air in a space. The chiller unit changes the temperature of water by using a heat pump or absorption refrigeration. It can also lower the humidity of air by condensing steam or other substances.

Chiller units play a very important role in any organization. They function by removing heat from the air conditioning systems and then cooling it down to a colder temperature before it can enter into the air that is supplied to offices and other spaces. The advantages of these units include: increased productivity, reduced costs, and unparalleled creativity while writing content for different use cases

What Are the Applications of Water Chillers?

Chilled water units are more massive in terms of mechanical construction. They are widely used for dehumidification and cooling fluids in industrial setups.

Moreover, they have applications in refrigeration processes.

Industrial Chillers Application

What Are Evaporative Chillers?

Evaporative chillers are alternatives to water chillers. Usually, they range from 15 to 200 tons.

What Are the Best Applications for Evaporative Chillers?

Evaporative chillers are best suited to a single facility. They maximize heat rejection.

What is an Average-sized Chiller?

Commercial chillers start from 1 ton and can go up to 500 tons in size. It mainly depends on your requirement what size of chiller you need.

What is an Average-sized Chiller Unit Price?

Chiller unit price starts as low as $2000, and they can go up to $12000 and more. An average-sized chiller can cost you around $4000 or more.

Moreover, you can also find many chiller units for sale so that they may be cheaper than average market rates.

chiller condenser

How Much Does a Chiller Unit Cost?

Chiller units generally cost more. Firstly, it depends upon the type of chiller. Water chillers are usually cheaper. Therefore, at Geson Chiller, you can get a competitive price for any chiller size.

How Does a Commercial Chiller Unit Work?

If you talk about the working principle, it is like industrial chillers. However, commercial units may be smaller.

water cooled chiller system working principle

How Can You Size a Chiller Unit?

The size of your water chiller depends on three factors i.e.

- The temperature of the incoming water

- Required chilled water temperature

- The flow rate of the water.

For an industrial setup, you must be using a commercial water supply to be understandably more massive.

How to Install a Chiller Unit?

It depends on the type of chiller that you wish to install. Generally, the process is lengthy and slightly complicated.

So, when you purchase from Geson Chiller, you will also get a complete installation guide for flawless installation.

air chiller unit

Can You Install a Chiller Unit HVAC at Home?

Yes! You can install chiller units at home too. Usually, you will need an air-cooled split unit for home applications. However, you will need appropriate space for your chiller unit, HVAC.

chiller unit hvac

How to Install a Chiller Unit in a Non-commercial Space?

The installation procedure of a chiller in a non-commercial space is not too different. However, you might need special permission from the local authorities for chiller installation.

If you are installing a cold water chiller unit, you need permission because water chillers require cooling towers.

Where Can You Find the Best Chiller Unit?

Whether you are based in China or anywhere globally, you can get an excellent deal for your chiller requirements at Geson Chiller. There is a wide variety and price range to choose from.

chiller fan coil unit

What Are the Best Chiller Unit Models?

Currently, we have state-of-the-art chillers in various types. Some of the highlights are:

- The GSAH Air Cooled Screw Chiller, with a 500-ton capacity.

- GSWH Water Screw Chiller with precise controllability up to 0.5 0C.

Can You Import Chiller Units from China?

Yes, you can import chillers from China too. Let us know your required size, and we will guide you to the best chiller unit for your office or home.

Air Cooled Chillers system Diagram

What Are the Things to Consider When Importing a Chiller Unit?

When importing a chiller, take care of the following aspects:

- Go through customer opinions.

- Double-check the authenticity of customer reviews

- Get in touch with the customer service of your preferred brand. It will help you to analyze how customer-oriented the company might be.

- Consult your peers who have imported a chiller unit previously.

What is the Best Chiller Unit Brand?

In terms of quality, cost-effectivity, and durability, the Geson Chiller is the best in the market.

Whether it’s a cold water chiller unit, air-cooled split unit, or air-cooled scroll chillers, there is a wide variety in size, price, and applications.

room chiller unit

What Are the Advantages of Chiller Units?

Chiller units are more expensive in terms of installation and ease of use. However, you can reap their benefits for a long time.

They are more efficient, highly durable, and give you better control over the cooling environment, so they are much better for temperature control applications.

Where Can You Install Chiller Units?

It depends on the application, type, and size of the chiller compressor. Generally, you can install chillers in mechanical rooms with other industrial equipment.

Also, you can install them outdoors with the cooling outlet towards the process that requires chilling.

chiller indoor unit

How Good is the Chiller Unit Market?

The chiller unit market has prospered in the last five years. As per the figures, chiller unit sales are expected to rise in the coming years because of industrialization.

chiller unit for cold room

Will Chiller Units Survive in the Future?

Whether it’s air chillers or water chiller units, they are here to stay simply because they are highly valuable equipment.

Especially for industrial needs, chillers are very important. Moreover, we are likely to see more solar-powered chillers in the future that will be more environmentally friendly and fuel-efficient.

chiller unit working principle

In Which Countries Are Chiller Units Used the Most?

Countries with more industrial setups tend to use chillers most. Moreover, chillers are widely used in the Middle East because of the hot climate.

Also, European countries, America, and Eastern Asian countries are places where chillers have vast applications.

cold room chiller unit

Are Condenser And Chiller Units the Same?

No. Chillers use compression techniques to reduce liquid temperatures. On the other hand, condensers convert vapors into liquids.

On What Principle Does Chiller Units Work?

Chillers use a pumping system that circulates either Glycol or cold water to a condensation system. Then, the dispersed liquid cools down the process and returns with a higher temperature.

How Can You Start a Chiller Unit?

Starting a chiller requires careful inspection and assurance of several factors. Here are things to consider:

- Inspect signs of leakages and general cleanliness of the area.

- Check all the pressure gauges for any uncalibrated readings.

- Ensure that the switches and pumps are functioning properly

- Lubricate the motors

- Verify all the electrical connections

- Tightly fix loose ends and plugs.

- Ensure that the protection devices are working

- Perform strength test of the major components

- Ensure that there is sufficient lubrication oil

- Check the refrigerant quantity.

Once ensured, you can now start the chiller unit.

Which Gas is Suitable in a Chiller Unit?

You can find several gases for different temperature ranges. For instance, if you want to chill water above freezing temperatures, water will be enough for cooling. Ammonia gas fillings are needed for lower temperatures.

Therefore, any temperatures below -20 C require Ammonia gas as a refrigerant. Furthermore, there are R12, R123a gases too, but they are toxic and are subject to many environmental regulations.

What is Meant by the Chiller Unit Set Point?

The Chiller unit setpoint is the desired cooling temperature. Geson Chiller offers precise set point control through the Siemens PLC with a precision of up to 0.5 0C.

How Does a Chiller Unit Trip?

Often chillers can trip because of low load. There can be several other reasons too. Check out this video to learn more about chiller tripping:

What Do You Mean by Antifreeze in the Chiller System?

When the ambient conditions are chilly, and Antifreeze can prevent your chiller system from flash freezing. Hence, you will need an anti-freeze if your supply temperature is less than ten 0C.

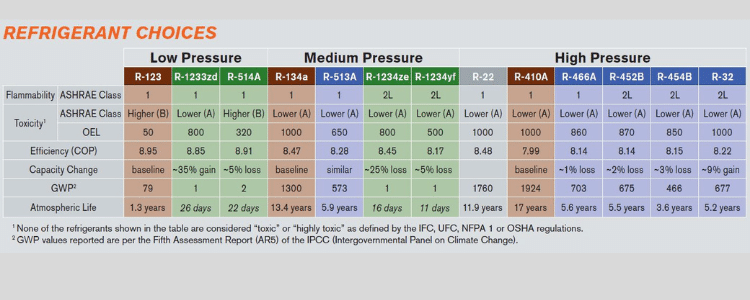

Refrigerant-Choices-Chart

What Kind of Process Chillers are There?

Process chillers unitare a type of refrigeration system that removes heat from a process fluid to a lower temperature.

The most common type Process chillers is the plate chiller, which forces the process fluid through rows of plates that contain coolant that is at a lower temperature than the fluid. Process chillers can be used for meeting higher demand or as an emergency back up when another chiller may fail.

Another type Process chillers is the shell and tube heat exchanger which has tubes with coolant on one side and water on the other side, passing through small channels in layers called plates.

How Can You Maintain a Chiller Unit?

Manufacturers often give a detailed maintenance guide about chiller maintenance. However, always remember to:

- Maintain proper refrigerant levels

- Maintain a daily log

- Purge air regularly

- Perform weekly checks of water treatment

- Inspect and clean the internal tubes.

How Can You Troubleshoot Issues in Chiller Units?

A chiller is a combination of various parts. Therefore, troubleshooting a chiller plant requires professional expertise. Here is a video to help you troubleshoot chiller issues.

What is VGD?

VGD is short for Variable Geometry Diffuser. In chillers, VGD feedback is a variable resistor internal to the actuator.

ac chiller unit

List Down the Components of a Chiller Unit?

- Compressor

- Condenser

- Expansion Valve

- Evaporator

- Water Box

- Power Unit

- Control Unit

- Fan

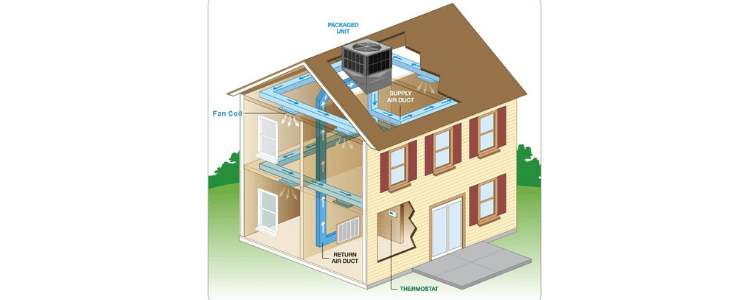

Figure 5 HVAC System

How to Fill Gas in A Chiller?

Filling gas can be a tedious process, especially if you are working on bigger chiller units.

What is the Chiller Unit Price?

Ask our engineer, we will do the customized design for you.

Offer the best chiller unit price for you, and ensure the best quality for you is our principle.

Contact Geson Chiller engineer now, there are all types of chiller units for sale.

What Safety Precautions Should You Follow for Your Chiller?

- Turn off breaker before cleaning and checking

- In case of fire, electrical storm, or earthquake, stop the chiller operation

- Avoid touching the control panel with wet hands

- Never touch the wiring inside the panels

- Stay clear of high voltage cables

- Don’t keep any flammable substance near the chiller

- Make sure all the problems resolve before turning on the chiller

- Never climb the chiller

- Stop operation if you smell gas

- Never touch any parts of the fans

- Restrict chiller area to authorized personnel

- Avoid pouring water near the chiller

- Stop the purge pump for oil replacement

- Stop operation when combustion smoke is black

- Never touch the absorbent

- Check for physical damage before starting the chiller

- Don’t play with the set values

- Use the appropriate power supply

- Always seek professional help for repair and maintenance

chiller ac unit

Conclusion

Chiller Unit sales are expected to rise in the coming years. As we speak, more efficient and cost-effective chiller units are being introduced every year. Therefore, such vital applications of chillers make them a significant industrial need. They are efficient and durable in the longer run.

You can get some of the best chiller units at Geson Chiller. Whether it’s a single house unit, a commercial, or industrial chillers, we have solutions for your needs. So, whether you’re based in China or anywhere globally, let us know what you need and we will be there for you.