-

Use R134a refrigerant to help contaminate the environment.

-

Large refrigeration capacity

- GESON Hydroponic Chiller Features:

-

From fresh water and salt water, anti-corrosive pure titanium evaporators can provide you with the best quality.

-

Equipped with a high flow rate

-

Control system is easy to use.

-

It also has a smooth, quiet operation.

| Model NO. | GS-10ASHT 10Ton hydroponic chiller | Application Fields |

Commercial & Industrial Field

|

| Certification | ISO, CE | Condition | New |

| Ambient Temp. | T1 or T3 Tropical Climate | Option 1 | Hydronic Module |

| Option 2 | Heat Recovery | Option 3 | Free Cooling |

| Option 4 | Low Ambient Temperature Cooling | Option 5 |

-10℃~25℃ Customized Inlet/Outlet Water Temperature

|

| Transport Package | Plastic Film Wrapped/ Polywood Case | Specification | 150kW-1400kW |

| Trademark | GESON or OEM | Origin | China |

| HS Code | 8418 | Production Capacity | 1000 Sets |

| Business Type: |

Manufacturer/Factory, Trading Company

|

| Main Products |

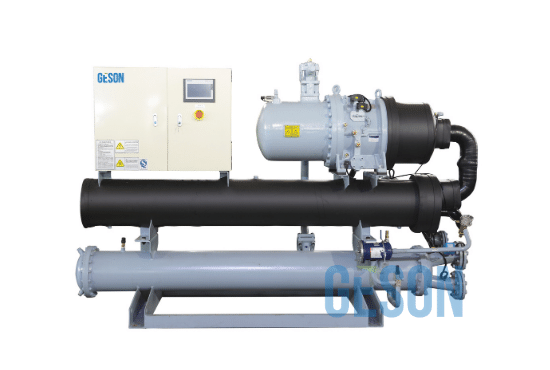

√ Water-cooled chillers √ Air-cooled process equipment chillers √Screw Chillers √ Scroll Compressors chillers √ Modular Chillers √ HVAC Chillers √ Industrial Water Chillers √ Air Cooled Screw Chiller √ Air Cooled Scroll Chiller √ Packaged Chiller Systems √ Centrifugal chillers √ Liquid Chillers √ Evaporation Cooled Chillers √ Water(ground) source heat pumps √ Air source heat pumps √ Swimming Pool Heat Pumps, Swimming Pool Chillers and etc.

|

| Applicaiton Industries: |

Pharmaceutical clean room, Chemical industry, Plastic Injection mold cooling, and Extruding Molding Industry, Artificial Real Ice Rink Projects, Environmental Simulation Laboratory, Computer Server Room, Telecommunications Stations, Food and Beverage Processing Cooling, Cold Storage Room, Die casting, Rubber, Printing and many other Industries. Hotel, Swimming Pool, Hospital Heating Water Supply System, House Heat Water System, and other Heat Pump Projects.

|

| Management System Certification: |

ISO 9001, ISO 14001

|

| Main Markets: |

South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East

|

| Terms of Payment: | LC, T/T |

| OEM/ODM Availability: | Yes |

Geson Very Best Chillers is one of the leading China Chiller Manufacturers.

Geson chiller systems is leading manufacturer specializing on Industrial water chillers and commercial HVAC water chillers manufacturing for over 15 years.

Geson Chiller systems offer one-stop chiller system solutions with the highest quality and safest products to customers globally.

You can get all types of typical capacities ranging, chilling systems typical cooling capacities from 3 Ton~4500 Ton, and temperature from -145℃~25℃, complete full product series for Geson chilling systems.

| Trade Capacity | |

| International Commercial Terms(Incoterms): | FOB, CFR, CIF, EXW |

| Terms of Payment: | LC, T/T |

| Average Lead Time: | Peak Season Lead Time: 1-3 months, Off Season Lead Time: 1-3 months |

| Number of Foreign Trading Staff: | 4~10 People |

| Export Year: | 2014 |

| Export Percentage: | 41%~50% |

| Main Markets: | South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East |

| Nearest Port: | Shanghai Port, China,Ningbo Port, China |

| Import & Export Mode: | Exportation via agency |

| Production Capacity | |

| Address: | Nanjing City, Jiangsu Province, China |

| R&D Capacity: | OEM, ODM, Own Brand(GESON) |

| No. of R&D Staff: | 5-10 People |

| No. of Production Lines: | 4 Lines |

| Annual Output Value: | US$5 Million – US$10 Million |

The Best Hydroponic Chiller: An Innovative Method of Growing Plants | GESON

What is a hydroponic chiller and what are they used for?

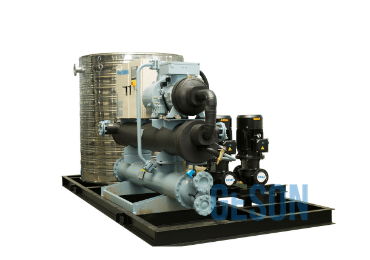

The vegetable hydroponic chiller is developed, designed and produced by GESON Chiller,

Strictly follow national and international standards.

Has a sound quality management system and production equipment.

The main purpose is to cool down the plant nutrient solution in the nutrient solution circulating tank.

Since hydroponic vegetables are grown on pipes, there is no soil at the roots,

All growth is provided by nutrient supply through nutrient solution for hydroponics,

Therefore, the temperature control of the nutrient solution for hydroponics is extremely critical to its growth.

How does a water chiller work for hydroponics?

The nutrient solution and water are mixed in the tank,

The hydroponic vegetables nutrients is pumped to each row of laid hydroponic vegetable pipes through the pipeline pump,

Provide nutritional supplements to vegetables,

Water hits each row of vegetable tubes to exchange heat with the vegetables.

It absorbs a lot of heat from vegetables and causes the water temperature to rise.

The increase in plant nutrient solution temperature is extremely unfavorable for the growth of vegetables.

In order to facilitate the growth of hydroponic vegetable,

It is necessary to control the hydroponic temperature to a certain temperature in order to maximize the production benefits.

Why GESON hydroponics chiller is best water chiller for hydroponics?

To address customer concerns,

Our company has developed this best water chiller for hydroponics.

Its simple working principle is that the small water chiller hydroponics cools the recirculating hydroponic system,

When the the hydroponics temperature and humidity is reached,

Then, the pipeline pump is pumped to each row of vegetable pipes to supply nutrients to the hydroponic vegetables.

The hydroponic chiller can be used according to the user’s use requirements, use environment, and use methods.

What is recirculating hydroponic system?

Recirculating hydroponic system is a circulating liquid temperature control equipment,

The hydroponic nutrients solution flows through the evaporator (heat exchanger) of the chiller equipment for heat exchange,

The hydroponic nutrients solution can be cooled rapidly,

What the features of GESON hydroponic chiller?

- The compressor is selected internationally, with built-in safety protection, low noise and power saving.

- The electrical part adopts international brand “LG” products, the machine works stably and has a long service life. 3. Imported pumps from Italy and Taiwan famous factories, with large flow, long-lasting.

- Equipped with imported precision digital temperature controller, which can control the water temperature ±1°C and set the temperature range from 3°C to 50°°C.

- All stainless steel thick water tank evaporator, built-in automatic water replenishment and other devices, easy to clean and maintain.

- The condenser of the hydroponic chiller is a casing type, with an inner threaded copper tube, with reasonable design and good heat exchange effect;

Flanging and warping sheet mechanical expansion process and heat exchanger production line.

- Electrostatic spray plastic shell, Europeanized design, beautiful and generous,

the outer panel adopts the form of quick disassembly and assembly, which is convenient for use and maintenance. Unit performance

Multiple compressors are used in parallel,

and each compressor has its own independent cold water circuit, that is, the evaporator and condenser are also completely independent;

all compressors are controlled by a unified microcomputer control system, which is turned on and off one by one and is completely isolated from each other.

It will not interfere with each other.

In addition, are imported and original, and the failure rate of a single machine is extremely low.

Based on the above reasons, this series of machines can have a highly stable performance under the condition of continuous operation for many years.

What is good water temp for hydroponics?

It’s essential to maintain the temperature of the water in a hydroponic system between 65-70 degrees Fahrenheit in order to optimize plant growth.

If the temperature falls below at this point, plants will see it as the end of summer and will go to sleep. Growth slows until the temperature rises again. In this case, you’ll need a heat source rather than a cooling system

Thankfully, we also have cold water coolers for those in need. They’re much cheaper than an icemaker unit and allows you to regulate the temperature of your water that might be too warm.

On the other hand, if temperatures raise outside of the healthy range plants will be unable to hold onto dissolved oxygen. Dissolved oxygen is a necessary compound for nutrient absorption. A warmer nutrient solution is also prone to pest invasion. Plus – the heat can even stress your plants to the point of halting growth entirely.

The ideal temperature for a hydroponic system is between 65 and 75 degrees Fahrenheit. Use a Hydroponic Chiller or a thermometer to monitor your TS levels, and adjust as necessary!

What is the GESON hydroponic chiller Configuration?

For the instability of use in various industries,

In the production and processing process of the hydroponic chiller, the personnel of our company’s R&D department also select the core components of different brands according to different user requirements.

In the selection of compressors, we have always focused on imported brands.

Compressor

Japanese brands: Daikin series, Sanyo series, Panasonic series;

French brand: Taikang series;

American brands: Copeland series, Meiyoule series;

Taipei brand Fusheng series, Hanbell series;

German brands: Bitzer series, etc.

Condenser and Evaporator

There are shell and tube type, fin type, coil type in style,

There are copper tubes, titanium alloys and stainless steels in the selection of materials.

Circulating pump

We also use different brands and materials according to the different needs of different industries, such as Taiwan’s Yuanli, Yuanxin, Yuanhe, Yuanshen, etc., Nanfang stainless steel pump, Auckland and German Wilo, etc.

Electrical appliances

LG, Schneider, Siemens, etc.,

Control System

Microcomputer board, single module, PLC, etc., Bangpu, Jieke, etc.

In order to strengthen the stability and safety of the water cycle ice water equipment during use,

In the process of production and processing, the EU quality system management certification has been actively introduced.

Control product quality step by step in the selection of suppliers,

And strictly regulate the load,

In the performance of the unit, phase loss, reverse phase protection devices, motor overload protection devices, high and low-pressure protection devices, water shortage automatic alarm devices, and low temperature and anti-icing protection devices are added.

Please contact us today for more information about our hydroponic chillers or to request a quote.

All Types of Industrial Water Chiller Products

Who We Are?

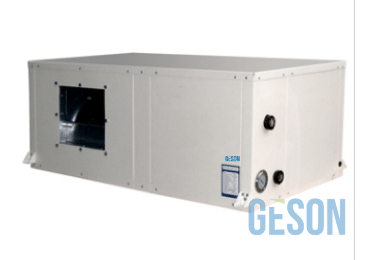

Are you looking for a professional air chiller manufacturer?

Geson chiller focuses on Industrial/Commercial air chiller unit over 15 years.

Air Chiller Unit, also known as an Air-Cooled Chiller, is a kind of equipment that uses cooling methods to cool the equipment to achieve the technological purpose in a variety of industries with different processes. It is widely used in Pharmaceutical, Chemical, Plastic Injection mold cooling and extruding machinery, Computer data center room, Food and Beverage process cooling, Cold storage room, MRI and Laser machine, and other central air-conditioning projects. Because the source of heat exchange is gas and it is equipped with a special electric fan, it is called “air cooling”.

Geson Chiller Air-Cooled Chillers are divided into Air-Cooled Screw and Scroll Chillers.

Easy maintenance and low water loss make Geson Chiller’s Air-cooled Chillers very suitable for areas with water scarcity or with poor water quality.

If you have more questions about water chillers, free to Contact Us.

Advantages of Geson Chiller

Your expert chiller manufacturer in China

Your Top Quality Chillers Manufacturer In China

Методы заправки хладагента – Чиллер GESON

Методы заправки хладагента - Чиллер GESON Заправка хладагента является важным и сложным этапом при установке и обслуживании [...]

Refrigerant Charging Methods-GESON Chiller

Refrigerant Charging Methods-GESON Chiller Refrigerant charging is an important and complex step in the installation and maintenance [...]

Понимание ключевых различий между COP, EER, APF, SEER, IPLV и NPLV в охладителях тепловых насосов кондиционеров воздуха

Разница COP, EER, APF, SEER, IPLV, NPLV кондиционера теплового насоса чиллера 1. COP (COP= холодопроизводительность/электрическая мощность [...]

Understanding the Key Differences between COP, EER, APF, SEER, IPLV, and NPLV in Air Conditioning Heat Pump Chillers

Difference of COP, EER, APF, SEER, IPLV, NPLV of Air Conditioning Heat Pump Chiller 1. COP [...]