- Chilled water temperature -15~0℃

- Refrigerant types: R22/R134A/R407C/R410A and etc.

- Compact in structure, cover small area, save machine room space.

- Cooling capacity ranges: 30~4500RT

- Loading adjusted 100%, 75%, 50%, 25%,0.

- Completely running tested before the delivery from the factory.

- Cooling capacity ranges: 10HP~80HP

- Built in a water tank and water tank

- Easy for maintain and service.

- Scroll compressor is long-life operating and easy to maintain.

Why Choose Geson Brewery Glycol Chiller?

A brewery is a type of factory or business that is mainly involved in brewing beers. The place where the beers are made is called a brewery. It is made up of a brewing plant that has its own brewing equipment for the production of commercial beers.

Brewing beers is an activity that has been around since 2500 BC. It was initially an industry that was developed at home until the demand for beers grew and it was necessary to build dedicated breweries for large-scale production.

There is a diverse array of breweries now in existence. They differ in terms of the brewing processes, degrees of automation, and the type of beer produced.

The use of glycol chiller system large brewery, required major breakthroughs that enable them to achieve the same quality beer consistently. The modern brewery employs both heating and cooling solutions such as glycol chiller brewery for quality control purposes.

The use of glycol chiller for breweries is the standard in the industry today. If you are considering the brewery-glycol-chiller for this purpose, you need to know a little information to help you decide on the right system to use.

We can supply the following types of industrial glycol cooling systems:

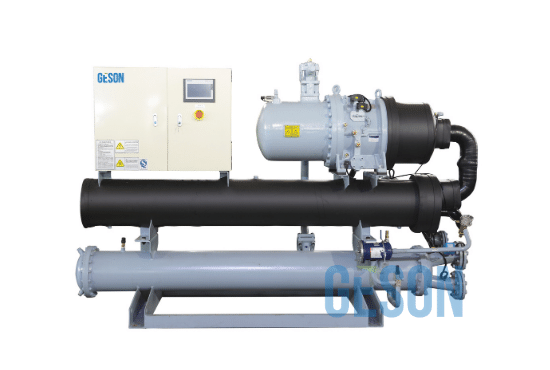

- Screw Chillers

- Centrifugal Chillers

- Rotary Screw Chillers

- Scroll Chillers.

- You can get the following services:

- Customize chiller types, compressor types.

- Precious chilled water temperatures.

- The most suitable economical refrigerant.

- The OEM brand for your brand.

- Stable operation with 40000 hours failure-free.

- Customize the voltage as your need.

Contact our engineer, to get the right solution for your breweries.

All Types of Industrial Water Chiller Products

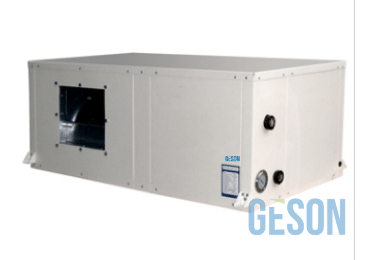

Modular Air Chiller

Advantages of Geson Chiller

We want to be your expert chiller manufacturer in China

Your Top Quality Chillers Manufacturer In China

Top Brand Components

Ensure Your Top Quality Chiller

Applications

Chiller For Plastic Industrial

Beer And Wine Fermentation Chiller

Chemical Processing Chiller

Computer Data Center Chiller

Food And Dairy Chiller

Hotel HVAC Chiller

MRI And Laser Chiller

Pharmaceutical-Formulation-chiller

Swimming-Pool-chiller

Brewery and Distillery Glycol Chiller System | GESON Glycol Chiller

A brewery is a type of factory or business that is mainly involved in brewing beers. The place where the beers are made is called a brewery. It is made up of a brewing plant that has its own brewing equipment for the production of commercial beers.

Brewing beers is an activity that has been around since 2500 BC. It was initially an industry that was developed at home until the demand for beers grew and it was necessary to build dedicated breweries for large-scale production.

There is a diverse array of breweries now in existence. They differ in terms of the brewing processes, degrees of automation, and the type of beer produced.

The use of glycol chiller system large brewery, required major breakthroughs that enable them to achieve the same quality beer consistently. The modern brewery employs both heating and cooling solutions such as glycol chiller brewery for quality control purposes.

The use of glycol chiller for breweries is the standard in the industry today. If you are considering the brewery-glycol-chiller for this purpose, you need to know a little information to help you decide on the right system to use.

What is a Glycol Chiller Brewery?

Glycol Chiller Brewery

A brewery glycol chiller system is a type of cooling unit, that makes use of propylene glycol, which is a type of anti-freeze agent. In some cases, they also use a combination of propylene glycol and water.

The brewery glycol chiller is designed to remove excess heat during the brewing process. That heat is dissipated toward a heat exchanger system or a refrigeration system.

A glycol brewery chiller is, therefore, able to maintain the ideal temperature that is necessary to produce the best quality product or brew.

Where Is a Glycol Chiller Used in Brewery Applications?

There are several methods with which a brewery glycol chiller system is implemented in this industry. Some of its most notable applications include glycol chiller brewery fermentation, two-stage heat exchangers, wort, brite tanks, and more.

Other industry-specific applications of Glycol Cooling System include brew house chiller, nano-brewery chiller, and brewing counterflow chiller. There is also an option for glycol chiller for nano-brewery.

Why Do I Need a Glycol Chiller?

A glycol chiller is a refrigeration system that uses organic antifreeze. This cooled liquid is fed through a looped circuit that is connected via tubes or pipes to the chiller’s input and output section.

The use of a chiller in a glycol beer chiller is deemed beneficial as it decreases the freezing point of the process fluid. By regulating temperature, it helps to ensure that there is a continuous flow in the system’s operating temperature.

Brewery Glycol Chiller System

What Are The Types of Glycol Chiller Brewery?

There are three general types of glycol chiller brewery that you can choose from. It is important to know about each of these types so you can choose the right one to use.

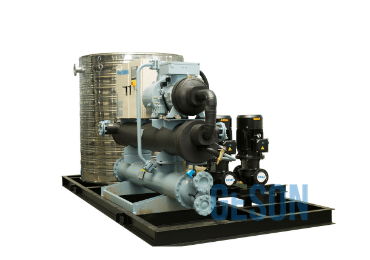

- Packaged Chillers – Packaged chillers are complete units that are made up of one tank and a pump. This is a convenient solution for smaller breweries because the essential components are available in one chiller. This is also suitable for outdoor installation if you have limited space indoors.

- Modular Chillers – This type of glycol chiller brewery can be added inline to a process. It is a popular choice among breweries that are expanding. As long as you have the correct pipe sizes, you can add modular chillers as the chiller demand of your brewery expands, too. The only downside to this type of chiller is that it is not as energy-efficient as the modular units do not operate as one.

- Split Chillers – This is the best choice of glycol chiller for breweries with limited space. You can install the heat exchanger outside.

Does Glycol Improve Heat Transfer?

Glycol – ethylene or propylene – is known to have a higher vapor point. It is able to absorb heat at higher temperatures with more efficiency without reaching boiling point.

Despite its lowest vapor point, water is able to carry more heat per unit. The use of a larger tube in a brewery glycol chiller system has a larger wall surface area. It results in an improvement in heat transfer.

Brewery Glycol Chiller

How Often Should You Change Glycol in a Glycol Brewery Chiller?

There is no definitive answer on the frequency of changing the glycol as a coolant to your chiller system. However, experts recommended changing it once a year for maximum performance and cooling capacity.

What % Glycol Goes in a Chiller for Brewery?

A brewery glycol chiller uses either propylene glycol or mixes it with water in order to facilitate better circulation and transfer of heat. By removing heat from the brew, you can achieve better taste and quality.

Once the heat had been transferred, the propylene glycol flows to the system and back to your brew. When mixing glycol with water to produce efficient refrigeration, the ideal percentage is 60 percent glycol and 40 percent water.

This is the ideal percentage when mixing glycol with water to boost its antifreeze properties. It is the best mixture when you need to achieve rapid cooling.

Glycol Chiller For Nano Brewery

What is the Density of Glycol Solution for Brewery Chiller?

The density of glycol solution in a brewery chiller will depend on the requirement for the system. As mentioned above, the ideal ratio is 60/40 for glycol and water. It varies depending on the type of glycol used.

The density of ethylene glycol is 1.11 g/cm³ and 1.04 g/cm³ for propylene glycol. The appropriate concentration of glycol in a chiller is at least 25%.

But again, you have to adjust it based on your cooling requirements and it is best to use a glycol refractometer to ensure the right density and concentration.

What Formula Do I Use for Brewery Glycol Chiller Load Calculator?

The ideal formula to determine the amount of glycol to use in a brewery chiller is G = (%D-%P)/100-%P.

You must first determine the total volume in the brewery glycol chiller system. Make sure you estimate the capacity of the piping, too. To this formula, you must add the volume of the tank jackets.

The last step is to add the capacity of the chiller system reservoir in order to arrive at the total system volume.

How to Pipe a Glycol Chiller for a Brewery?

Building the brewery glycol chiller system involves the use of various materials. The use of the correct pipes is essential in order to facilitate proper cooling.

Copper is the most common type of pipe used for glycol chiller system breweries. It is a great option for glycol chillers because the pipes are rigid and can last for many years. The only downside with copper pipes is that they are expensive to acquire.

Pre-Insulated 80 PVC is the next most common option for glycol brewery chiller piping. It is popular because it is an economical choice. As long as installed properly, it performs well and does its job of maintaining the ideal temperature in a brewery.

ABS plastic piping is another choice to add for glycol brewery chiller piping. This one is also pre-insulated and can be quite expensive. The ABS plastic piping material is engineered for chilled water applications so it is the number one choice for many breweries.

You can also use other alternatives for economical tank piping solutions. Your two options include Cross-Linked Polyethylene and Nylon Braided Rubber Hose.

10 Ton Brewery Glycol Chiller

What Do I Use to Fill a Glycol Chiller in Brewery?

The most common method to fill a brewery glycol chiller with the coolant is via a funnel or hose connection. Another alternative method to fill the system with glycol is the pump the water and glycol solution to the chiller’s drain connection via a portable pump.

When filling the glycol chiller for the brewery, make sure that all the vents are open.

What Size Glycol Chiller Do You Need for Your Craft Brewery?

There is a wide range of sizes available for a brewery glycol chiller system. It will depend on what type of brewery you are using it for. The common applications are craft breweries and small breweries.

Sizing is very important because you want to make sure that you achieve high efficiency with your brewing solution. If you are not sure about which size to choose, you can use the brewery glycol chiller load calculator that is available online and in suppliers of chiller systems.

We offer a wide range of sizes to choose from so you can find the right fit for your needs. We have small brewery chiller glycol, 10-ton brewery glycol chiller, and portable glycol chiller brewery.

China Glycol Chiller For Brewery

What is the Ideal Brewing Temperature?

It depends on the type of beer that is being brewed. Every type of beer requires a specific fermentation temperature in order to achieve the best quality and taste. Setting the ideal temperature for brewing will depend on the type of beer you want to produce.

This is something that you need to take into account when choosing a glycol chiller for the brewery. You want to make sure that the system you choose is able to generate the chiller capacity for your intended brewing result.

If not, then you can seriously compromise the quality and taste of your beers. Setting the brewing at a lower temperature than the ideal can lead to incomplete fermentation. This can affect the taste of the beer and it will produce inconsistencies with the result.

Glycol Chiller System Large Brewery

Glycol Chiller Brewery – Figure 3

How Do You Perform Glycol Chiller Brewery Condenser Cleaning?

A dirty condenser is one of the reasons why a High Head Pressure Alarm happens to your brewery glycol chiller system. This typically happens during peak load periods and if the ambient temperature goes up.

Make sure you clean the condenser as part of the chiller maintenance for breweries. Check the finned surface on the condenser and use a fine brush to gently wipe away the dirt. Make sure that there are no obstructions to the coil and try not to bend the fin surface.

You need to contact a technician if the plugin the condenser is too much for you to clean on your own. Professionals use a specially formulated cleaning agent for the coil to avoid causing damage to the system.

Small Brewery Chiller Glycol

Why Is A Brewery Glycol Chiller Essential During Fermentation?

The fermentation process in a brewery produces heat during the process. While some of the heat is transferred onto the environment, it is important to use a glycol chiller in order to maintain the temperature and ensure that the brewery does not get too hot.

Without glycol chiller for the brewery, it can result in a difference in the temperature of your beer by up to 10 degrees Celsius during fermentation. This temperature difference can create a significant difference in terms of the taste and quality of the produced beer.

The difference in temperature can also create an unpredictable reaction from the yeast in the beer mixture. As a result, there might be inconsistency with this batch of beers from the previous ones.

How Do You Size Glycol Chiller for Nano Brewery?

Choosing the right size of brewery glycol chiller system for a nano-brewery can be tricky. It might seem economical for you to choose a size of chiller according to your current needs, it is also best to think of future expansion plans.

Many would suggest the modular chiller for breweries as you can add them according to your needs as you expand the operation. However, experts recommend that you use a variable control drive chiller to avoid oversizing the chiller system.

This is a step towards making sure that you choose a system that delivers the highest level of energy efficiency. Choosing a variable drive compressor is the smartest decision you can take when you have space restrictions and there are intentions to expand in the future.