Why Choose GESON Chiller?

GESON compression chillers is a mature technology product.

Adopts the famous brand compressors from Danfoss,Matsushita,Copeland,Bristol or Bitzer.

You can get the lowest cost for your project.

It can use the electric power directly.”

Geson industrial water chiller can meet all your varies of requirements.

You can get the water chillers capacity from 3 Ton~4500 Ton, and temperature from -145℃~25℃, complete full product series for customers.

We can supply the following types of industrial water chiller:

- Screw Chillers

- Centrifugal Chillers

- Rotary Screw Chillers

- Scroll Chillers.

- You can get the following services:

- Customize chiller types, compressor types.

- Precious chilled water temperatures.

- The most suitable economical refrigerant.

- The OEM brand for your brand.

- Stable operating with 40000 hours failure-free.

- Customize the voltage as your need.

Geson chiller has is widely applied in the Commercial facilities, Pharmaceutical clean room, Chemical industry, Plastic Injection and extruding industry, Artificial Real Ice Rink projects, Environmental simulation laboratory, Computer server room, Telecommunications stations, Food and Beverage processing cooling, Cold storage room, Die casting, Rubber, Printing and many other industries.

Contact our engineer, to get the right solution for your industry.

- 50~400ton cooling capacity.

- -5℃ chilled water temperature supply.

- Loading adjusted 100%, 75%, 50%, 25%,0

- 40000 hours failure-free stable operating.

- High efficiency copper and aluminum fins condenser.

- SIEMENSE PLC controller.

- Polywood case package, protect the water chiller in the delivery.

- Cooling capacity ranges: 30~4500RT.

- Loading adjusted 100%, 75%, 50%, 25%,0.

- Stable outlet temperature, precious 0.5℃.

- Failure-free operation >=40000hours.

- Available with R22/R134A/R407C/R410A and etc.

- Schneider electric parts, SIEMENS PLC touch screen controller;

- Compact in structure, cover small area, save machine room space.

- -5~25℃ outlet temperature

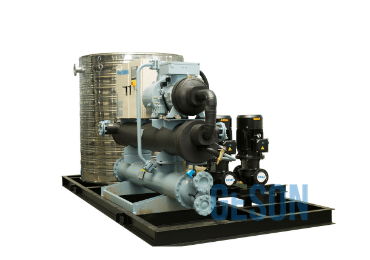

- Built-in a water tank and water tank

- A scroll compressor is long-life operating and easy to maintain.

- Completely tested before the delivery.

- Can customize according to the customer’s need.

GESON Compression Air Cooled Chiller Manufacturing

|

|

|

|

|

|

Air Cooled Screw Chiller Datasheet |

|

| Model | GS-600WD |

| Cooling Capacity (kW) | 600 |

| Total Power (kW) | 123 |

| Refrigerant | R410A |

| Compressor Type | Semi-closed 5:6 asymmetric twin-screw compressor |

| Leaving Water Temp (℃) | 7 |

| Entering Water Temp (℃) | 12 |

| Shipping Weight (kg) | 2570 |

| Operating Weight (kg) | 2700 |

| Length (mm) | 3300 |

| Width (mm) | 1050 |

| Height (mm) | 1900 |

All Types of Industrial Water Chiller Products

Modular Air Chiller

Advantages of Geson Chiller

We want to be your expert chiller manufacturer in China

Your Top Quality Chillers Manufacturer In China

Applications

Chiller For Plastic Industrial

Beer And Wine Fermentation Chiller

Chemical Processing Chiller

Computer Data Center Chiller

Food And Dairy Chiller

Hotel HVAC Chiller

MRI And Laser Chiller

Pharmaceutical-Formulation-chiller

Swimming-Pool-chiller

Compression Air Chillers System

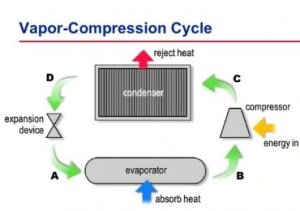

A compression chiller is a type of chiller system that uses a compressor in order to convert a low pressure and low temperature refrigerant into vapor form. From there, the vapor is compressed so that it decreases in volume and it raises the temperature and pressure of said gas. This is an important process for this type of chiller before the refrigerant is fed into the condenser coils to remove any excess heat.

Compression Air Chillers System Supplier in China | GESON Chiller

When you mention compressors, you often think of it as a part of the HVAC system. In reality, compressors play a more crucial role than that in terms of a cooling system, such as a compression chiller. If you are trying to decide what chiller system is the most appropriate one to use for your intended project or industrial use, then you have come to the right place.

Find out all the things you need to know about a compression chiller in this FAQ guide. All the questions you have about choosing the right chiller and how a compression chiller works will be answered here.

What Is A Compression Chiller?

A compressor is the most important component of a compression chiller. It is important for both heating and cooling systems. The compressor is essential as it determines the overall performance of the system and helps it achieve thermodynamic efficiency. The compressors are also responsible for a huge chunk of the system’s energy consumption. If you want to make your system more efficient, then spend some time looking at how compressors can impact that.

This component of a compression chiller also accounts for up to 40 percent of the entire system’s cost. Aside from the performance and efficiency, make sure you look into the cost of these parts, as well.

Air Cooled Chiller

What Does A Compression Chiller Do?

A compression chiller is a type of chiller system that uses a compressor in order to convert a low pressure and low temperature refrigerant into vapor form. From there, the vapor is compressed so that it decreases in volume and it raises the temperature and pressure of said gas. This is an important process for this type of chiller before the refrigerant is fed into the condenser coils to remove any excess heat.

What Is The Main Purpose Of A Compressor?

The main purpose of a compressor is to transform a gas refrigerant with a low temperature and low pressure into one that is high in pressure and high in temperature. This compression enables the gas to flow through the condenser. Once in the condenser, the refrigerant will transport to the coils in order for the heat to be removed from the refrigerant to achieve the cooling effect.

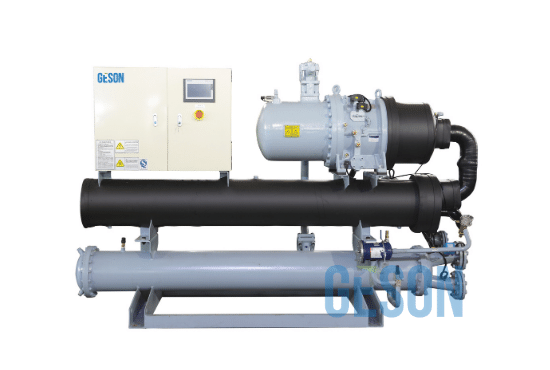

Water Cooled Chiller

How Many Compressors Does A Chiller Have?

The amount of compressors needed in a compression chiller will vary based on the size of the types Of Chiller. Take this as an example: you have an 80-ton chiller. A compression chiller of this size might have four 20-ton compressors. This will mean you have two compressors on each side of the refrigerant circuit.

All of the compressors present in the system must work together efficiently. In any event that one of the compressors fail, this can lead to a loss of capacity. The chiller will still function but you will loss part of the cooling output – meaning, you won’t be able to achieve the maximum cooling capacity of the compression chiller (compared to when all compressors are working).

How Does Vapor-Compression Chiller Technology Work?

A chiller is made up of different parts that have separate functions in order to produce the desired cooling effect. The compressor is one of these parts and it generates cooling with a process known as vapor compression. A compression chiller is typically made up of the following types of compressors: screw compressor, reciprocating compressor, scroll compressor, and centrifugal compressor.

The compressors that are found within this chiller system are commonly driven by a semi-hermetic or hermetic configuration. This is known as the most common method of making compressors work since it is known to be effective and efficient, particularly in terms of cooling a refrigerant. It also does not require exhaust ventilation or fuel supply in order to work.

The cooling effect from the system is generated using a method known as vapor compression. Refrigeration compressors work as a pump for the refrigerant gas. The total capacity for the compressor (as well as the chiller itself) is measured using the kilowatt (KW) input, along with the horsepower unit and volumetric flow.

The exact mechanism with which the chiller operates will vary depending on the specific type of compressor used. Therefore, it is very important that you select the right compressor type as it can impact the effectiveness in cooling and energy-efficiency of the overall system.

What Are The Different Types Of Compressors In Industrial Chillers?

There are four main types of compressors used in industrial compression chiller.

These four types of compressors are reciprocating compressor, screw compressor, centrifugal compressor, and scroll compressor.

Centrifugal Compressor

The centrifugal-type compressor is characterized by a large volute-shaped pipe that curls around the condenser.

The refrigerant enters the system through the suction line. From there, it enters the center of the impeller wherein it is directed by the blades. These blades have a constant rotating motion to create an angular velocity that enables the refrigerant to travel.

The high velocity produced by the blades allows the refrigerant particles to fly out in all directions and to generate increased pressure before it goes to the condenser. The centrifugal compressor is one of the most commonly used types of compressors in industrial applications and large buildings.

Screw Compressor

The screw compressor is another type Of Chiller that is commonly used in a compression chiller. You can find this in both air cooled chiller systems and water cooled chiller systems. The main difference between the two is that the compressor is located on top of the chiller with the water cooled systems. On the other hand, the screw compressor is located under the chiller for air cooled systems.

Within the screw compressor are two interconnected screws. The refrigerant will enter through the void between those screws and as soon as they rotate, it will push the refrigerant further into the compressor so that it will exit in high pressure and with high temperature. From the compressor, the refrigerant goes to the expansion valve.

Screw compressor

Reciprocating Compressor Chiller Components

A reciprocating compressor is also known as the piston-type compressor found in a compression chiller. As the name implies, it compresses the refrigerant using pistons that move in an up and down direction within the cylinder. It works on the principle of reciprocation wherein the refrigerant moves back and forth in order to generate pressure to compress it. The use of parts like piston and cylinder makes it similar to a car engine in terms of operation.

Scroll Compressor Chiller Components

The final type of compressor commonly used in a compression chiller is the scroll compressor. It involves two parts: one orbiting scroll and another fixed scroll. These two scrolls work together to compress the refrigerant in a continuous manner. This type of compressor is very common in chiller systems for hotels, clinics, and office buildings.

Do All Chillers Have Chiller Compressor Parts?

Yes. Compressors are an integral Chiller Compressor Parts or any other chiller systems. It plays a very important role to compress the refrigerant into vapor form before it is passed onto the evaporator. Without the compressor, you won’t be able to convert a low-pressure and low-temperature gas into one that is high pressure and high temperature.

In terms of the type of compressor used, it will largely depend on the size and capacity of the compression chiller.

Figure 2: Compression chiller

Which Type Of Compressor Is Most Efficient?

According to experts, the reciprocating compressor is the most efficient type of compressor. The multi-stage compressing activity gives it higher efficiency level. It also enables the system to produce better cooling and to have a longer life span.

Figure 1: compression chiller types

Which Compressor Is Used In Industry?

All types of compressors in a compression chiller are widely used in various industries. The specific type of industry they will be used in is where the difference lies. The reciprocating (also known as piston-type) compressor is commonly used in mobile industrial applications. The rotary screw compressor is also widely used for large-scale industrial chiller needs.

How Do You Choose A Compressor?

There are several factors you need to take into account when choosing a compressor for your compression chiller. The first factor is the size. The size of the compressor must match the capacity of the cooling load and the area that you wish to be cooled (or the desired level of chilled temperature).

Operation

You should also consider the operation of the compressor and how it behaves when used in a compression chiller system. For example, screw compressors are known to be loud when in operation (as compared to scroll compressors). Therefore, screw compressors might not be an ideal choice for applications that require a quiet operation, such as hospitals and schools.

Cost

The cost of the compressor and its installation must also be taken into account. The reciprocating (or piston-type) compressors are the cheapest ones available in the market. On the other hand, screw compressors are the most expensive.

Operating Cost

In addition to the cost of acquiring the compressor parts, you should also consider the operating cost and efficiency when choosing one for a compression chiller. Screw and reciprocating compressors have nearly the same level of efficiency under the same conditions. You should also look into the energy consumption for the compressor type.

Reliability and Maintenance

The reliability and maintenance of the compressor is one more factor for you to consider when choosing the right one for your Water Chiller System. A reciprocating compressor in a compression chiller consists of more moving parts when compared to a centrifugal compressor (has the least number of parts). Due to the number of parts, the reciprocating compressor is more vulnerable to wear and tear. The latter would require frequent maintenance to ensure that it is working properly.

Water Chiller System

Other Factors

In addition to the factors above, there are other considerations you have to make when choosing a compressor for a compression chiller. These other factors include the field serviceability, design and operation of the compressor, and the type of refrigerants used.

Figure 3: How does a compressor work?

Which Compressor is Better: Rotary or Piston?

The rotary and piston-type (also known as reciprocating) compressors are two that are most commonly used in a compression chiller. Thus, these two are also often compared from each other in terms of use in a chiller system.

The rotary compressor used in a compression chiller is simpler in operation. Experts say that it is also more durable and more efficient. However, reciprocating compressors can also be efficient, as long as you have the right size chiller for the intended use.

When you choose a piston-type compressor, you can expect higher air quality, better energy efficiency, more uptime (and less downtime), cost-effectiveness, and a system that has a longer life span. In this regard, a piston-type compressor has the edge, but it will depend on what the compression chiller is used for.

What Is The Working Principle Of A Compressor?

The working principle of a compressor is very simple.

The air is compressed in order to decrease the volume of the refrigerant (usually in gas form). The process also causes the pressure to increase. A piston or screw is used in order to generate that compression activity that can increase the temperature and pressure of a gas.

What Is Good Compression Ratio?

The ideal compression ratio in a Water Chiller System is anywhere from 8:1 to 10:1. If you achieve a higher ratio that goes up to 14:1, it means that you have achieved higher combustion efficiency. The higher the ratio and combustion efficiency, the more power you can get with few exhaust gases and less fuel.