Why Choose Geson Chiller Cooler?

Are you looking for a professional industrial water chiller cooler manufacturer?

Here, you will have the ultimate economical solution.

You can get the water chillers cooler capacity from 3 Ton~4500 Ton, and temperature from -145℃~25℃, complete full product series for customers.

Including Water-cooled chiller cooler, Air-cooled chiller cooler, Screw chiller cooler, Scroll Chillers, Centrifugal chillers, Water(ground) source heat pumps, Air source heat pumps and etc.

Geson has been exported to the Americas, Europe, Middle East, Africa, Southeast Asia, and its, and was praised by customers all over the world.

If you have more questions about water chiller cooler, free to contact us.

- 5~25℃ chilled water temperature supply.

- 50~400ton cooling capacity.

- Loading adjusted 100%, 75%, 50%, 25%,0

- Branded screw compressors, simple structure, few breakdowns.

- High efficiency copper and aluminum fins condenser.

- Polywood case package, protect the water chiller in the delivery.

- Cooling capacity ranges: 30~4500RT.

- Loading adjusted 100%, 75%, 50%, 25%,0.

- 35% higher efficiency with high COP.

- Available with R22/R134A/R407C/R410A and etc.

- SIEMENS PLC controller.

- Compact in structure, cover small area, save machine room space.

- Can add the heating function to customizing the design.

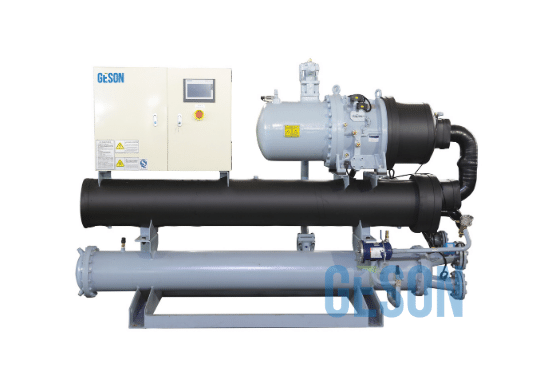

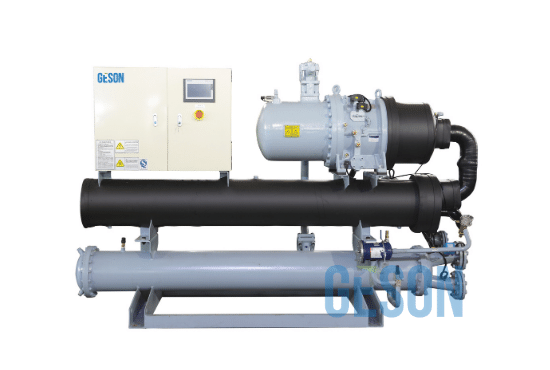

Water Chiller Cooler Specification

|

| Cooling Capacity (kW) | 350 |

| Refrigerant | R407C |

| Compressor Type | Semi-closed 5:6 asymmetric twin-screw compressor |

| Leaving Water Temp (℃) | 7 |

| Entering Water Temp (℃) | 12 |

| Shipping Weight (kg) | 3160 |

| Operating Weight (kg) | 3575 |

| Length (mm) | 3900 |

| Width (mm) | 1250 |

| Height (mm) | 1800 |

Advantages of Geson Chiller

We want to be your expert chiller manufacturer in China

Your Top Quality Chillers Manufacturer In China

Top Brand Components

Ensure Your Top Quality Chiller

Applications

Chiller For Plastic Industrial

Beer And Wine Fermentation Chiller

Chemical Processing Chiller

Computer Data Center Chiller

Food And Dairy Chiller

Hotel HVAC Chiller

MRI And Laser Chiller

Pharmaceutical-Formulation-chiller

Swimming-Pool-chiller

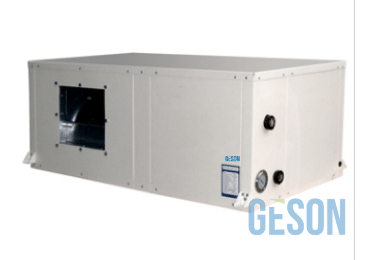

All Types of Industrial Water Chiller Products

Modular Air Chiller

Chiller Cooler Water Chiller Cooler-The Ultimate FAQ Guide

A chiller cooker is one of the most invaluable pieces of equipment known to modern industry. It provides easy access to cooling when desired. Like most chiller systems available in the market, chiller cooler comes in a variety of sizes, shapes, and designs. It is important to stay abreast on this technology and the different devices that are available for installation so that you can choose the best system to suit your intended purpose.

What Is A Chiller Cooling System?

The chiller cooling system is a complex process of compressing a refrigerant to remove excess heat and then expanding it to release cooled air (while removing excess heat back into the atmosphere). The use of chiller cooler equipment is one way to facilitate cooling in a given space, such as a room or a building.

Each modular chiller system is comprised of a number of different components. These components need to work seamlessly together to ensure that you can get maximum cooling results.

Figure 1 – What is chiller cooler

What Types of Chiller Coolers are There?

There are water cooled chillers, air cooled chillers.

All these chiller systems are widely applied in the industrial process cooling.

Water chiller systems is combined with the water cooling tower.

How Does A Chiller Cooler Work?

A chiller cooler is a type of machine that uses vapor compression technology to remove heat from a liquid or refrigerant. There are also other methods of removing excess heat to produce a cooling effect, such as absorption refrigeration. The liquid is then circulated through a heat exchange process in order to produce the desired level of low temperature.

The wasted heat is produced as a necessary by-process of the refrigerant. This heat is released back into the ambient air in order to achieve maximum efficiency. In some cases, such as when the chiller system is used for heating, the excess heat is recovered. For compression chillers that operate using vapor compression, there are several types of compressors to choose from.

The chiller cooler is the equipment or apparatus by which the chilled air or water is exhausted in order to provide cooling for a given space or building. Over the years, there have been many types of coolers that were introduced into the market. One such example of a chiller cooler is the evaporator cooler.

The evaporator cooler is a natural and energy-efficient way to provide cooling by evaporating water into the air. This equipment relies on a principle of using outdoor air to generate cooling by passing it over water-saturated pads. This process encourages the evaporation process of the water wherein it is directed into the home or building to provide as low as 15 degrees Fahrenheit of cooled air.

As with any other types of chiller systems, there are different options available for a chiller cooler in the market. It is important to educate yourself about these options so you can choose the right size for your needs, as well as ones based on the installation process. The operation of the unit is also a crucial factor that will help you determine the best chiller cooler in the market.

What Is The Chiller Cooler Difference Between A Chiller Vs Cooler?

The term chiller and cooler are often interchanged with one another. However, there is a significant difference between the two. A chiller cooler is therefore different from any other systems that you might find in industrial use.

First off, a chiller is a system or machine that is responsible for generating cooled air, which is a result of many processes that eliminates excess heat from water or air. The chiller machine is used in many applications including HVAC systems, food processing, and many more.

On the other hand, a cooler is any machine or equipment that is capable of cooling. It refers to the apparatus or container that can be cooled or kept cool, but it is not capable of producing the cooling effect on its own.

How Is Chiller Load Calculated?

There is a formula that you must follow in order to calculate the efficient chiller load for a particular system. It is also crucial in properly sizing the chiller cooler so that you can achieve maximum efficiency with the system.

There are three variables you need to know in order to calculate the ideal chiller cooler load: incoming water temperature, chilled water temperature, and the flow rate.

First off, you must determine the temperature differential by subtracting the required chill water temperature from the incoming water temperature. You must then calculate the BTU/hr with the temperature differential figure.

You can also compute the chiller load for a chiller cooler by oversizing the chiller by up to 20% (based on tons). This will give you the right chiller load so that the system won’t have to work too hard to generate the ideal cooking effect.

What Are The Main Components Of A Chiller Cooler?

There are several main components that make up a chiller cooler. These are as follows: condenser, expansion valve, water box, compressor, evaporator, power panel, and control units. Each of these components need to work together to ensure that you have a well-functioning chiller cooler.

The compressor is the prime component of the chiller cooler. It is responsible for building pressure difference that enables the refrigerant to move to other components of the chiller system. There are different types of compressors but it is always located in between the evaporator and condenser.

As part of the chiller unit, the compressor can either be mounted internally or externally. Since it is constantly working, it is also typically noisy.

The condenser is where the refrigerant is fed onto the compressor. It is also located right before the expansion valve. The main purpose of the condenser is to remove excess heat from the refrigerant before it is fed onto the evaporator. There are currently two options available for condensers in the market: air-cooled and water-cooled.

The main difference between the air-cooled and water-cooled condensers is the presence of a cooling tower. The air-cooled ones do not require cooling towers as they have exposed condenser pipes instead.

A chiller cooler also consists of an expansion valve. The main function of the expansion valve is to lower the pressure of the refrigerant while expanding it. This process also increases the volume of refrigerant in the process. This process enables it to pick up any unwanted heat for it to be eliminated later on.

As the expansion valve helps to expand the volume of the refrigerant, the evaporator is where unwanted heat will continue to be collected. This part helps to eliminate heat before the refrigerant is fed onto the cooling tower and the heat is released. At the end of this part, the “chilled water” is pumped to the entire building or space for the cooling effect.

The other parts such as the water box, power unit, and controls are designed to facilitate basic operation of the chiller cooler.

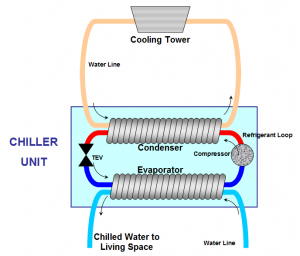

Figure 2 – Guide to chiller cooler

How Do You Increase The Efficiency Of Chiller Cooler?

There are three steps you can take to boost the efficiency of a chiller cooler. The first step is to consider the variable speed retrofits. You want to be able to maximize the use of variable speed drives on your chiller cooler unit so you can get the best setting for a specific application.

You can also try to run multiple parallel devices in order to maximize your energy savings. This is a more suitable move to higher efficiency since the equipment runs more efficiently when using part-load. And finally, you should increase the supply temperature.

How Do You Maintain A Chiller Cooler?

Proper maintenance is an important step to prolong the lifespan of a chiller cooler. As part of a commercial maintenance unit, it is important to keep a daily log so you know what parts are working and which ones need to get fixed.

It is also important to maintain the cleaning of the tubes in order to facilitate an efficient heat transfer. And regularly clean the condenser with water in order to prevent corrosion or scaling. When introducing water into the chiller cooler, make sure to use low water temperature to minimize damage.

If you are not sure about how to maintain a chiller cooler, you may seek the advice of an expert professional. They will be able to conduct a more thorough maintenance to avoid any hiccups with the system.

How Long Does A Chiller Cooler Last?

A chiller cooler is expected to last anywhere from 15 to 20 years. In some cases, it can even last for up to 25 years. This estimation is based on the assumption that the unit is used on average running conditions. It must also adhere to the recommended maintenance procedure so that every part works optimally.

Every type of chiller system and configuration will require a different approach to maintenance. Make sure you pay close attention to the specific type in order to maximize the lifespan of the chiller cooler.

What Is Chiller Cooler Efficiency?

It is pretty easy to calculate the chiller cooler efficiency. The efficiency of the unit is determined using the COP formula, which is also known as Coefficient Of Performance. This formula is determined by a ratio of the cooling effect produced by the chiller cooler and the amount of energy that is used to generate the cooling effect.

Figure 3 – chiller cooler

What Is The COP Formula?

The COP formula is determined by two variables: the power that is generated from the cooling unit (measured in kW) and the power that is supplied to power the compressor (also measured in kW). This is also the same formula that is used to determine the efficiency of the chiller cooler unit.

How Do You Choose A Chiller Cooler Manufacturer?

Choosing a chiller cooler manufacturer is an essential first step to ensure that you have a quality system in your hands. Make sure that you invest time in comparing among your options when it comes to manufacturers of chiller cooler so you can get your money’s worth.

The first step in choosing a chiller cooler manufacturer is to check the variety of systems available. It is important that you can get the right size of chiller cooler, as well as one that operates efficiently and is within your budget. Moreover, they should have a wide enough selection to offer systems from a lab to an industrial scale.

You should also consider the years of experience that the manufacturer has in the industry when choosing them to supply your chiller cooler. The longer they have been around in the industry, the more you can rely on and trust them to deliver quality products. It is not guaranteed but you can depend on them to do their best to protect their reputation by keeping their clients satisfied.

Geson is one of the leading providers of chiller coolers in the world.

They offer one of the best solutions when it comes to professional cooling systems.

Find the water chiller cooler that suits your requirements in their inventory of industrial-grade HVAC products of various cooling capacities and temperatures.

They also carry other types of chillers for residential, commercial, and industrial applications.

A water chiller cooler is a special type of refrigeration equipment that uses water as its secondary refrigerant.

It circulates condenser water from the cooling tower to condense the main refrigerant.

Water chiller coolers are popular industrial machines that have found its way into many commercial and residential settings.

Figure 1. Water Chiller Cooler

What are Chiller Coolers Used for?

Technically speaking, a water chiller cooler is used to lower the circulating water’s temperature.

These chillers come in a closed-loop system that facilitates heat exchange from the water through the refrigerant.

These chillers are commonly use in large-size facilities and process cooling factories. They are also used for district cooling applications.

What are the Advantages of Using a Chiller Cooler?

The use of water as a secondary refrigerant is an inexpensive and non-toxic way of cooling areas and surfaces.

Additionally, liquid cooling is more efficient compared to air cooling.

Water has a high capacity for specific heat, thus allowing for a more efficient transfer of heat over a distance at atmospheric pressure and room temperature.

How Much Electricity Does a Chiller Cooler Use?

The amount of electricity a water chiller cooler uses will depend on its make, build, and capacity.

Chillers of variable speeds usually operate at 0.32 to 0.29 kilowatts per ton.

The power consumption of water chiller coolers may also increase or decrease according to usage and ambient outdoor conditions.

Which Gas is Commonly Used in a Chiller Cooler?

There are different gases or refrigerants that can be used in a water chiller cooler, but the most common of them all is ammonia.

Ammonia or R717 is a halogen-free chemical that is popular among water chiller coolers because of its high rating of heat absorption.

Its atomic structure is also perfect for use in smaller water chiller coolers, more particularly the portable types.

How Does a Chiller Cooler Work?

A water chiller cooler works following the principles of vapor absorption or compression.

The process starts when the transfer of heat takes place, at which point the refrigerant starts to evaporate.

As the refrigerant transforms from a liquid form into vapor form, the temperature of the coolant reduces.

Figure 2. Water Chiller Cooler Diagram

What is the Purpose of a Chiller Cooler?

A water chiller cooler is used mainly to facilitate the continuous flow of the coolant to achieve the desired temperature of the process water.

As the coolant is pumped through, the heat is extracted from one area to another, thereby cooling the atmosphere around it.

This is why manufacturers use a water chiller cooler in a facility where there are many machines and pieces of equipment that are heat sensitive.

Where is a Chiller Cooler Used?

Since a water chiller cooler is used to cool machines and products, they are commonly seen in factories and similar manufacturing facilities.

The different applications of water chiller coolers mostly include processes that involve injection molding cooler or tool and die-cutting.

Many experts also install water chiller cooler in processing plants that produce food, beverages, chemicals, lasers, semi-conductors, and machine tools, among others.

Which is Better: Air or Chiller Cooler?

There are pros and cons between an air and water chiller cooler. But when it comes to efficiency, water chiller coolers reign supreme.

Experts recommend water chiller coolers to users who prefer a more portable solution and a quieter operation.

However, water chiller coolers are very flexible because they can also be used in commercial-scale applications.

Is a Chiller Cooler the Same as a Freezer?

Chillers are freezers are two different pieces of equipment.

Freezers are appliances or rooms that are used to store perishable items, like food, at a temperature that is below 0 degrees Celsius.

Coolers, on the other hand, are machines that generate cold air for different uses, such as to regulate the temperature of the room.

A water chiller cooler removes heat from liquids through the vapor absorption or compression technique.

What is the Correct Temperature for a Chiller Cooler?

The ideal temperature setting for a water chiller cooler will depend on the machine’s applications or the user’s requirements.

However, the common setting is between 2 to 7 degrees Celsius or 35 to 45 degrees Fahrenheit.

In an industrial setup, a temperature setting of 10 degrees Celsius or 50 degrees Fahrenheit is quite common.

What is the Function of the Condenser in a Chiller Cooler?

The high-pressure gas coming out of the compressor will enter the condenser where the process of removing heat takes place.

As the gas cools, it transforms into a liquid form. It will then travel through the system and enter back through the evaporator.

In this particular type of a chiller, the water from the cooling tower condenses and cools the refrigerant.

Figure 3. Water Chiller Cooler Cooling Tower

What is the Best Chiller Cooler Efficiency?

Every chiller has a Coefficient of Performance or COP, which refers to the ratio of the device’s cooling or refrigeration effect against the amount of power it uses.

A water chiller cooler achieves its maximum efficiency when it produces great tonnage with low kilowatt usage.

Water chiller coolers that can produce the lowest ECWT or Entering Condenser Water Temperature at 70% load is very efficient.

How Do You Increase Chiller Cooler Efficiency?

To increase water chiller cooler efficiency, start with retrofitting the machine to follow variable speeds.

Running several parallel devices will also optimize the user’s savings because water chiller coolers run more efficiently at a partial load.

Increasing supply temperatures will also help greatly.

Can a Chiller Cooler be Used for Heating?

A water chiller cooler may function as heat recovery device.

They can provide water temperatures that are suitable for heat recovery when operated at elevated refrigerant condensing temperatures, which is ideally at 105 degrees Fahrenheit.

Be sure to check the specifications of your water chiller cooler if it supports this feature.

What Chiller Cooler Size Should You Get?

To know what water chiller cooler size you need, you have to do some calculations.

Compute the temperature differential, BTU per hour, and cooling capacity.

Once you obtained these values, be sure to oversize it by 20% to get the right capacity that you need.

What Causes a Chiller Cooler to Trip?

Different factors may trigger low-pressure trips in water chiller coolers.

The most common causes are low refrigerants, low water flow, broken power assembly capillary, clogged water filters, dirty screens, and mud coating on the tubes.

If your water chiller cooler trips, be sure to consult with an HVAC technician to assess the situation.

How are Chiller Coolers Rated?

Typically, the rating of water chiller coolers is between 50 kilowatts and 7 megawatts.

That is equivalent to 170,000 BTU per hour and 24 million BTU per hour, respectively.

Check the rating of the water chiller cooler that you want to buy to know if it suits your needs.

How Do You Go About Chiller Cooler Maintenance?

Proper maintenance of a water chiller cooler is essential to preserve its optimal working condition.

An HVAC technician can help you keep the chiller in tip-top shape, mostly by keeping its tubes clean and treating the condenser water to prevent scaling and corrosion.

They will also lower the entering water temperature and maintain the flow rate of the chilled water between 3 to 12 feet per second.

How Do You Clean a Chiller Cooler?

There are different methods of cleaning a water chiller cooler and the ways of an HVAC expert prove supreme.

However, there are do-it-yourself methods that may also work.

Be sure to first check with a trusted technician to know if cleaning your water chiller cooler with buckets of water can help.

Why is the Chiller Cooler Not Cold?

There are many reasons why your water chiller cooler is not cooling the air optimally.

One of the most common reasons for that is a blown fuse or circuit breaker and some loose wiring.

If you are having problems with your water chiller cooler, contact an authorized service provider to help you determine the cause of the problem.

What Causes Low Evaporator Pressure on a Chiller Cooler?

If your water chiller cooler seems to have low evaporator pressure, then the problem might be the compressor not getting enough refrigerant.

This happens when the compressor can’t draw as much refrigerant into its cylinders.

As a result, the system’s entire low side will experience a notable decline on its pressure level.

How Long Should a Chiller Cooler Last?

With proper maintenance, a water chiller cooler can last for over 25 years.

The average lifespan of these machines is between 15 and 20 years.

Regular maintenance is the key to the long life of this equipment as it has several moving parts that require frequent checking.

What are the Components of a Chiller Cooler System?

The key components of a water chiller cooler system are the condenser, evaporator, compressor, chilled water pumps, heat exchangers, and cooling towers.

It also requires hydronic specialties such as air separators, chemical feed pots, and water pressure regulators.

Make sure that each of these components is in its best condition to ensure the seamless functionality of the machine.

What Chiller Will Work Best for Your Needs?

Water chiller cooler systems come in various sizes and designs.

There are a lot of small, portable, and localized units available, but there are large central water chiller coolers as well.

Know how you intend to use the water chiller cooler before buying so you can get the best solution for your needs. Contact the experts here at Geson for more information.

Why Should You Get a Geson Chiller Cooler?

Geson has over 15 years of experience in the heating and cooling industry.

Our manufacturing experience and highly knowledgeable engineering team is our promise of quality.

Geson is the one-stop-shop for all process cooling solutions serving the global market.

What are the Features of a Geson Chiller Cooler?

The Geson water chiller coolers come in various cooling capacities and variable load adjustments.

Most of our water chiller coolers are compact, structured, and have space-saving features. However, you can always get one customized to your needs.

Our machines also come with a guarantee of a fail-free and safe operation of over 40 thousand hours.

Where Can You Use a Geson Chiller Cooler?

Many of our clients have used a Geson water chiller cooler for their commercial and industrial facilities.

They have found uses for the chiller in pharmaceutical laboratories, plastic injection plants, and computer server rooms, among others.

They also use them in their food and beverage process cooling applications, die casting, and metal printing.

How Can You Buy a Geson Chiller Cooler?

Geson is a market leader in water chiller coolers worldwide.

Based in Nanjing, Jiangsu Province in China, we can practically ship our products almost anywhere in the world.

Contact our knowledgeable customer service personnel for your inquiries, quotations, and orders.

Aside from Chiller Coolers, What Other Products Does Geson Offer?

On top of our state-of-the-line water chiller coolers, Geson also manufactures other heating and cooling equipment such as heat pumps, HVAC chillers, and process chillers, among others.

If you have any questions about our products, feel free to call us or send us a message.

A service professional will contact you the soonest and provide for your requirements.

How Can I Be Sure of the Quality of a Geson Water Chiller Cooler?

Our many years in the industry and our reputation in the global market is your assurance of quality, safety, and reliability.

Our support group is always ready to help you if you have questions or concerns.

Contact us to know more about our company.