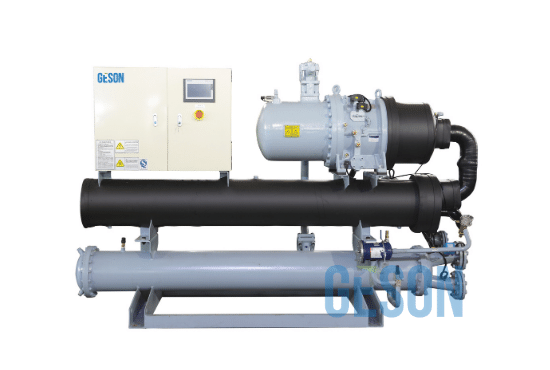

GESON Centrifugal Chiller Features:

- GESON high-efficiency variable frequency direct-drive falling-film centrifuge chillers breaks through many technical bottlenecks in the industry.

- GESON centrifuge chillers has developed core technologies with international leading levels such as horizontally opposed, single-shaft direct-drive, and full falling-film evaporation.

- GESON centrifuge chillers break through the bottleneck of small cooling capacity and improving the optionality of the project has become a more efficient and energy-saving choice for urban cooling.

GESON Centrifugal Chiller Benefits:

- Energy saving: COP up to 6.58, IPLV up to 10.72

- Leading technology: more than 20 patents

- Eco-friendly: less refrigerant charge and lower noise

- Flexibility: wider operation range but compact size

GESON Centrifugal Chiller Four Core Advantages:

-

High Efficiency and Energy Saving:

Under the national standard conditions, the whole series of GESON high-efficiency variable frequency direct-drive falling film centrifuges meet the national first-class energy efficiency standard for chillers, saving users a lot of air-conditioning operating costs. Compression and other cutting-edge technologies have become a more energy-efficient and efficient choice for cities.

-

Stable and Reliable:

frequency conversion technology reduces load energy consumption, a variety of famous and high-quality core components, and efficient operation of the system. Horizontally opposed compressor technology, single-shaft direct drive technology and strict production line inspection ensure the stable operation of GESON high-efficiency falling film centrifugal compressors.

-

Broadband Operation:

GESON high-efficiency variable frequency direct-drive falling film centrifugal unit compressor adopts the “broadband” design of variable pressure ratio, which is suitable for high-efficiency operation under multiple working conditions, and can be stably used in various system energy-saving solutions.

-

Quiet and Environmentally Friendly:

The innovative compressor structure greatly reduces the operating noise of the equipment. Under full load and full rotation speed, the noise is detected at a distance of 1m-1.5m from the unit in strict accordance with the national

-

Standard or AHRI Standard:

and the noise is 75-80dB (A), which is much lower than the noise of traditional screw machines and fixed-frequency centrifuges. The unit uses environmentally friendly R134a refrigerant, which has no damaging effect on atmospheric ozone.

GESON Centrifugal Chiller Description of Options:

The following are the optional accessories of GESON high-efficiency variable frequency direct drive falling film centrifuge.

Waterside Pressure

Evaporator: The standard design of the water side pressure is 1.0MPa, and there are 1.6MPa and 2.0MPa specifications to choose from

Condenser: Standard machine design water side pressure is 1.0MPa, and other 1.6MPa, 2.0MPa specifications are available

Shock Absorber

The standard machine is equipped with high-elasticity rubber shock-absorbing gasket, and a spring shock-absorbing device is optional to further reduce the vibration transmission of the unit to the load-bearing surface

Evaporator Insulation

The standard machine sticks 20mm thick F-grade high flame-retardant rubber-plastic insulation cotton on the evaporator shell, water chamber, end plate, suction pipe, and air supplement device.

When the relative humidity of the environment is as high as 75% and the dry bulb temperature is between 10 and 32.2 °C, the insulation layer can generally prevent condensation.

When the relative humidity is as high as 90% and the dry bulb temperature is between 10 and 32.2°C, a 40mm thick insulation layer can be selected

Refrigerant Isolation Valve

Isolate and store the refrigerant in the condenser without transferring the refrigerant for easy maintenance

Bulk Shipment

If the transportation channel space is limited and the whole machine cannot be hoisted, the chiller can be disassembled into several large pieces: compressor, evaporator, condenser, control cabinet, etc., and then transported and hoisted

Number of Heads

According to special application requirements, the unit can be configured with two heads

Flow Switch

The evaporator and condenser are equipped with a water pressure differential controller, optional water flow switch, random accessories, on-site installation

Package

The unit comes standard with transparent plastic film packaging for easy viewing of the hoisting holes, and wooden box packaging is optional

| Cooling capacity | RT | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1100 | 1200 | |

| kW | 2461 | 2637 | 2813 | 2989 | 3164 | 3340 | 3516 | 3868 | 4219 | ||

| 104kcal/h | 212 | 227 | 242 | 257 | 272 | 287 | 302 | 333 | 363 | ||

| Efficiency | Running power(1) | kW | 403 | 432 | 460 | 489 | 515 | 543 | 572 | 628 | 683 |

| COP(1) | kW/ kW | 6.11 | 6.11 | 6.12 | 6.11 | 6.14 | 6.15 | 6.15 | 6.16 | 6.18 | |

| Running power (2) | kW | 421 | 450 | 481 | 509 | 542 | 572 | 600 | 660 | 720 | |

| COP(2) | kW/ kW | 5.85 | 5.86 | 5.85 | 5.87 | 5.84 | 5.84 | 5.86 | 5.86 | 5.86 | |

| Business Type: |

Manufacturer/Factory, Trading Company

|

| Main Products |

√ Water-cooled chillers √ Air-cooled process equipment chillers √Screw Chillers √ Scroll Compressors chillers √ Modular Chillers √ HVAC Chillers √ Industrial Water Chillers √ Air Cooled Screw Chiller √ Air Cooled Scroll Chiller √ Packaged Chiller Systems √ Centrifugal chillers √ Liquid Chillers √ Evaporation Cooled Chillers √ Water(ground) source heat pumps √ Air source heat pumps √ Swimming Pool Heat Pumps, Swimming Pool Chillers and etc.

|

| Applicaiton Industries: |

Pharmaceutical clean room, Chemical industry, Plastic Injection mold cooling, and Extruding Molding Industry, Artificial Real Ice Rink Projects, Environmental Simulation Laboratory, Computer Server Room, Telecommunications Stations, Food and Beverage Processing Cooling, Cold Storage Room, Die casting, Rubber, Printing and many other Industries. Hotel, Swimming Pool, Hospital Heating Water Supply System, House Heat Water System, and other Heat Pump Projects.

|

| Management System Certification: |

ISO 9001, ISO 14001

|

| Main Markets: |

South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East

|

| Terms of Payment: | LC, T/T |

| OEM/ODM Availability: | Yes |

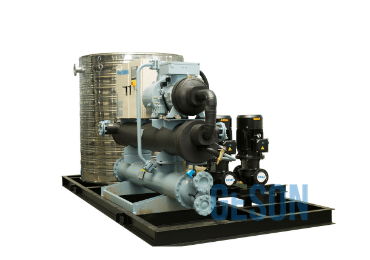

Geson Very Best Chillers is one of the leading China Chiller Manufacturers.

Geson chiller systems is leading manufacturer specializing on Industrial water chillers and commercial HVAC water chillers manufacturing for over 15 years.

Geson Chiller systems offer one-stop chiller system solutions with the highest quality and safest products to customers globally.

You can get all types of typical capacities ranging, chilling systems typical cooling capacities from 3 Ton~4500 Ton, and temperature from -145℃~25℃, complete full product series for Geson chilling systems.

| Trade Capacity | |

| International Commercial Terms(Incoterms): | FOB, CFR, CIF, EXW |

| Terms of Payment: | LC, T/T |

| Average Lead Time: | Peak Season Lead Time: 1-3 months, Off Season Lead Time: 1-3 months |

| Number of Foreign Trading Staff: | 4~10 People |

| Export Year: | 2014 |

| Export Percentage: | 41%~50% |

| Main Markets: | South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East |

| Nearest Port: | Shanghai Port, China,Ningbo Port, China |

| Import & Export Mode: | Exportation via agency |

| Production Capacity | |

| Address: | Nanjing City, Jiangsu Province, China |

| R&D Capacity: | OEM, ODM, Own Brand(GESON) |

| No. of R&D Staff: | 5-10 People |

| No. of Production Lines: | 4 Lines |

| Annual Output Value: | US$5 Million – US$10 Million |

The Complete Guide to Centrifugal Chillers | GESON Chiller

The Centrifugal Chiller is the most popular type of chiller in the world.

It is a water-cooled machine that cools air by removing heat from it.

This machine can be used in many different industries and applications, such as:

– Air conditioning systems

– Industrial processes

– Commercial refrigeration systems

– Residential refrigeration systems

– Laboratory refrigerators and freezers

Which Brand of Chiller is Best?

Trane Centrifugal Chiller

The Trane Centrifugal Chiller is one of the most popular chiller brands on the market today. It is a very efficient machine that has a high heat recovery rate.

One downside to this brand is that it has a higher cost than some other brands on this list.

York Centrifugal Chiller

The YK Centrifugal Chiller is also a popular brand because it has an excellent price point.

The only downside to this machine is that it requires more installation time than other models on this list.

Geson’s centrifugal chiller

Geson’s centrifugal chiller is an “absolute breakthrough in the field” of chiller technology.

Rather than relying on an external compressor to power the unit,

Geson’s centrifugal chiller uses thermodynamic principles to cool water.

Carrier Centrifugal Chiller

The Carrier Centrifugal Chiller is a more energy-efficient machine than the York Centrifugal Chiller, has a lower price point, and requires less installation time.

Daikin Centrifugal Chiller

The Daikin Centrifugal Chiller is a popular brand that has lower installation costs than other brands on this list.

Where Is The Rupture Disc Located On A Centrifugal Chiller?

The rupture disc is a safety device installed on centrifugal chillers.

The rupture disc prevents the pressure from building up in the system if there is a leak.

Rupture discs are also sometimes called pressure relief valves or safety valves.

The rupture disc is located in the center of the chiller and it’s usually installed at about a height of about six feet.

This is to allow for easy access to it when needed.

What is the Centrifugal Chiller Working Principle?

A centrifugal compressor chiller is a machine that changes heat energy into mechanical energy by a rotating impeller, and then use the mechanical energy to drive a refrigeration cycle to produce cooling.

There are two types of centrifugal compressor chillers: open type and closed type.

The open type is more common in the market, so it will not be discussed in this paper.

The closed type is basically an evaporator with a centrifugal chiller as the condenser.

It can be used for low-temperature cooling or vacuum coolin.

A type with a mechanical condenser can be used for vacuum-cooling or low-temperature cooling.

A type with a liquid condenser can be used for vacuum-cooling, low-temperature cooling, and also to make ice.

Centrifugal Chiller Diagram

Centrifugal Chillers are cooling systems that provide high efficiency and reliability.

What is the Centrifugal Chiller Components?

The centrifugal chiller components are the following:

– Compressor:

The compressor is a mechanical device that changes the refrigerant from a liquid to a gas.

It also pressurizes this gas so it can be pumped through the system.

– Condenser: The condenser is where the refrigerant gas changes back into a liquid, releasing heat in the process.

– Expansion valve: The expansion valve reduces pressure in the system by allowing some of the refrigerant to vaporize and escape to atmosphere.

– Evaporator:

The evaporator absorbs heat from inside an enclosure or building and converts it into cold, low pressure refrigerant.

This refrigerant then travels back through pipes to the compressor and starts this cycle over again.

What is the Centrifugal Chiller Refrigeration Cycle?

A centrifugal chiller is a refrigeration cycle that uses a compressor, condenser and evaporator to cool a liquid refrigerant.

The liquid refrigerant is pumped from the condenser through the evaporator where it is vaporized and then cooled back into a liquid by contact with the cold coils in the evaporator. This process is reversed in order to heat the gas in the chiller.

All Types of Industrial Water Chiller Products

Who We Are?

Are you looking for a professional air chiller manufacturer?

Geson chiller focuses on Industrial/Commercial air chiller unit over 15 years.

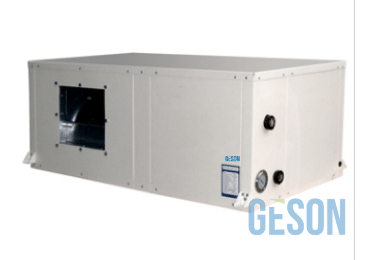

Air Chiller Unit, also known as an Air-Cooled Chiller, is a kind of equipment that uses cooling methods to cool the equipment to achieve the technological purpose in a variety of industries with different processes. It is widely used in Pharmaceutical, Chemical, Plastic Injection mold cooling and extruding machinery, Computer data center room, Food and Beverage process cooling, Cold storage room, MRI and Laser machine, and other central air-conditioning projects. Because the source of heat exchange is gas and it is equipped with a special electric fan, it is called “air cooling”.

Geson Chiller Air-Cooled Chillers are divided into Air-Cooled Screw and Scroll Chillers.

Easy maintenance and low water loss make Geson Chiller’s Air-cooled Chillers very suitable for areas with water scarcity or with poor water quality.

If you have more questions about water chillers, free to Contact Us.

Advantages of Geson Chiller

Your expert chiller manufacturer in China

Your Top Quality Chillers Manufacturer In China

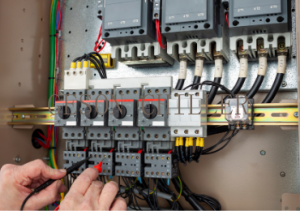

Top Brand Components

Ensure Your Top Quality Chiller

Applications

Chiller For Plastic Industrial

Beer And Wine Fermentation Chiller

Chemical Processing Chiller

Computer Data Center Chiller

Food And Dairy Chiller

Hotel HVAC Chiller

MRI And Laser Chiller

Pharmaceutical-Formulation-chiller