5 Ton Chiller Air-cooled Scroll Chiller Copland Compressor

| Model NO. | GS-05ASHT

5 Ton Chillers |

Application Fields |

Commercial & Industrial Field

|

| Certification | ISO, CE | Condition | New |

| Ambient Temp. | T1 or T3 Tropical Climate | Option 1 | Hydronic Module |

| Option 2 | Heat Recovery | Option 3 | Free Cooling |

| Option 4 | Low Ambient Temperature Cooling | Option 5 |

-10℃~25℃ Customized Inlet/Outlet Water Temperature

|

| Transport Package | Plastic Film Wrapped/ Polywood Case | Specification | 150kW-1400kW |

| Trademark | GESON or OEM | Origin | China |

| HS Code | 8418 | Production Capacity | 1000 Sets |

| Business Type: |

Manufacturer/Factory, Trading Company

|

| Main Products |

√ Water-cooled chillers √ Air-cooled process equipment chillers √Screw Chillers √ Scroll Compressors chillers √ Modular Chillers √ HVAC Chillers √ Industrial Water Chillers √ Air Cooled Screw Chiller √ Air Cooled Scroll Chiller √ Packaged Chiller Systems √ Centrifugal chillers √ Liquid Chillers √ Evaporation Cooled Chillers √ Water(ground) source heat pumps √ Air source heat pumps √ Swimming Pool Heat Pumps, Swimming Pool Chillers and etc.

|

| Applicaiton Industries: |

Pharmaceutical clean room, Chemical industry, Plastic Injection mold cooling, and Extruding Molding Industry, Artificial Real Ice Rink Projects, Environmental Simulation Laboratory, Computer Server Room, Telecommunications Stations, Food and Beverage Processing Cooling, Cold Storage Room, Die casting, Rubber, Printing and many other Industries. Hotel, Swimming Pool, Hospital Heating Water Supply System, House Heat Water System, and other Heat Pump Projects.

|

| Management System Certification: |

ISO 9001, ISO 14001

|

| Main Markets: |

South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East

|

| Terms of Payment: | LC, T/T |

| OEM/ODM Availability: | Yes |

Geson Very Best Chillers is one of the leading China Chiller Manufacturers.

Geson chiller systems is leading manufacturer specializing on Industrial water chillers and commercial HVAC water chillers manufacturing for over 15 years.

Geson Chiller systems offer one-stop chiller system solutions with the highest quality and safest products to customers globally.

You can get all types of typical capacities ranging, chilling systems typical cooling capacities from 3 Ton~4500 Ton, and temperature from -145℃~25℃, complete full product series for Geson chilling systems.

| Trade Capacity | |

| International Commercial Terms(Incoterms): | FOB, CFR, CIF, EXW |

| Terms of Payment: | LC, T/T |

| Average Lead Time: | Peak Season Lead Time: 1-3 months, Off Season Lead Time: 1-3 months |

| Number of Foreign Trading Staff: | 4~10 People |

| Export Year: | 2014 |

| Export Percentage: | 41%~50% |

| Main Markets: | South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East |

| Nearest Port: | Shanghai Port, China,Ningbo Port, China |

| Import & Export Mode: | Exportation via agency |

| Production Capacity | |

| Address: | Nanjing City, Jiangsu Province, China |

| R&D Capacity: | OEM, ODM, Own Brand(GESON) |

| No. of R&D Staff: | 5-10 People |

| No. of Production Lines: | 4 Lines |

| Annual Output Value: | US$5 Million – US$10 Million |

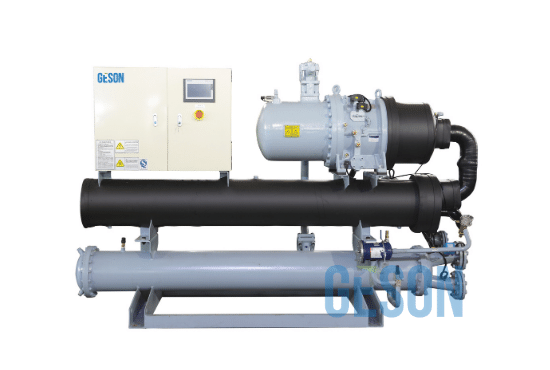

All Types of Industrial Water Chiller Products

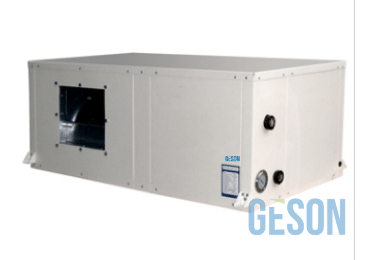

Modular Air Chiller

Who We Are?

Are you looking for a professional air chiller manufacturer?

Geson chiller focuses on Industrial/Commercial air chiller unit over 15 years.

Air Chiller Unit, also known as an Air-Cooled Chiller, is a kind of equipment that uses cooling methods to cool the equipment to achieve the technological purpose in a variety of industries with different processes. It is widely used in Pharmaceutical, Chemical, Plastic Injection mold cooling and extruding machinery, Computer data center room, Food and Beverage process cooling, Cold storage room, MRI and Laser machine, and other central air-conditioning projects. Because the source of heat exchange is gas and it is equipped with a special electric fan, it is called “air cooling”.

Geson Chiller Air-Cooled Chillers are divided into Air-Cooled Screw and Scroll Chillers.

Easy maintenance and low water loss make Geson Chiller’s Air-cooled Chillers very suitable for areas with water scarcity or with poor water quality.

If you have more questions about water chillers, free to Contact Us.

Advantages of Geson Chiller

Your expert chiller manufacturer in China

Your Top Quality Chillers Manufacturer In China

Top Brand Components

Ensure Your Top Quality Chiller

Applications

Chiller For Plastic Industrial

Beer And Wine Fermentation Chiller

Chemical Processing Chiller

Computer Data Center Chiller

Food And Dairy Chiller

Hotel HVAC Chiller

MRI And Laser Chiller

Pharmaceutical-Formulation-chiller

Swimming-Pool-chiller

What is a 5 Ton Chiller, Process Chiller, Portable Chiller, Outdoor Chiller and Water Chiller?

What is a 5 Ton Chiller?

A 5 Ton Chiller is a type of industrial air conditioning unit that can cool a large area.

A 5 Ton Chiller is an industrial air conditioning unit that can cool a large area.

This type of chiller typically has the ability to maintain a temperature in the range of 55 degrees Fahrenheit to 100 degrees Fahrenheit and has an efficiency rating of 8,000 BTU/hr.

How Does a 5 Ton Chiller Work?

A 5 ton chiller is a machine that cools water through the process of evaporation.

The water is pumped through the chiller and sprayed over a cooling coil.

As it evaporates, it cools the coil, which in turn cools the water.

The most common use of this machine is to chill drinking water for homes and businesses.

What are Some of the Different 5 Ton Chiller Applications?

There are many different uses of ai chiller in the food industry, marine industry and other industries.

One of the most prominent use cases is in the food industry.

AI chiller can be used to optimize the energy consumption, reduce water consumption and make sure that food stays fresh for longer periods of time.

How to Choose the Right 5 Ton Chillers for Your Industry

Choosing the right 5 ton chiller for your industry can be a daunting task.

It is important to know what you are looking for and what you need before you start shopping around.

The first thing that we need to do is determine the size of your system.

The size of the system will dictate how much refrigeration capacity it has and how much power it will need to operate.

We also need to know if we want a water-cooled or compressor type of chiller.

Water-cooled chillers are quieter than compressor chillers and they are more energy efficient, but they require a lot more maintenance and space for installation.

5 Ton Process Chillers Designed for Specific Industries

Process chillers are designed to cool the process fluids in industrial processes.

These are usually used in industries like oil and gas, chemical processing, food and beverage, pharmaceuticals and power generation.

The industries use process chillers to cool the process fluids at a specific temperature.

This is done so that the chemicals in the fluid do not react with each other or get too hot.

The fluid then flows through a heat exchanger where it transfers its heat to a cooling medium which is usually water or air.

This section focuses on how these 5 ton chillers can be customized for specific industry needs.

5 Ton Portable Chillers That Can Be Moved Around the Plant

Portable chillers are a great way to keep the temperature of the plant at a constant level.

They are also used in food and beverage processing industries as well as in manufacturing plants.

The 5 ton portable chillers can be moved around the plant and can be used in different places.

This is one of the reasons why they are so popular among companies that need to maintain a certain temperature on their premises.

Types of 5 Ton Chillers

A 5 ton chiller is a type of chiller that can provide cooling for up to 5 tons of refrigeration.

This amount is enough to cool an average sized restaurant or supermarket.

They are typically used in conjunction with a condensing unit and a water source.

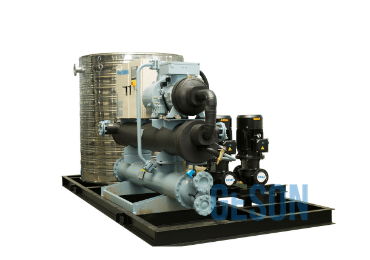

There are two types of 5 ton chillers: air cooled and water cooled chillers.

Air cooled chillers use outside air as the heat sink, which means they require more space than water cooled chillers, but they also cost less.

Water cooled chillers use the water from the condensing unit as the heat sink, which means they require less space than air cooled units and also cost more.

Process Chillers vs. Coolers

Process chillers are a type of refrigeration equipment that cools the process fluid by removing heat from the process fluid through a heat exchanger.

A cooler is a device for cooling down an object.

There are two major types of process chillers: air-cooled and water-cooled chillers.

Air-cooled chillers use ambient air to remove heat from the process fluid, while water-cooled chillers use water as the cooling medium.

Portable Chiller vs. Industrial Chiller

Portable chiller is a small device that can be easily carried from one place to another and used for chilling beverages. It is also called as a beer chiller.

These chillers are small, compact and energy-efficient devices which are perfect for home use.

Industrial chiller is a large device that can be used in industrial settings, such as manufacturing plants or warehouses.

It provides cold water to the plant through pipes and then the water gets cooled by various means like ice or refrigeration coils before it reaches the plant.

5 Ton Outdoor Unit Vs. 5 Ton Indoor Unit

A 5 ton outdoor unit is an air-cooled chiller with a water-cooled condenser.

The outdoor unit is used to provide chilled water to the air conditioning system.

It can be used as a standalone system, or in conjunction with an indoor cooling unit.

The 5 ton outdoor unit is usually mounted on the roof of a building, but it can also be installed on a ground level if there is sufficient space.

The outdoor units are usually installed in areas where there is no need for constant access to electricity and are often found in remote locations like factories, warehouses, and remote residential areas.

How a 5 Ton Process Chiller Can Save You Time And Money Down The Line

A 5 ton process chiller is a device that is used to cool down liquids, gases and solids.

A process chiller can be used in various industries such as food and beverage, pharmaceuticals, chemical processing and more.

The device is also known to reduce the time it takes for a process to complete by up to 50%.

A 5 ton process chiller can save you time and money down the line by reducing your production time.

5 Ton Outdoor Chillers That Can Be Used in Different Weather Conditions or Locations

Outdoor chillers are a necessity when it comes to keeping your drinks cold and refreshing.

These chillers are usually used in different locations or weather conditions, so it is important to find one that suits your needs best.

The following list includes the top 5 outdoor chillers that can be used in different weather conditions or locations.

– The first on the list is an outdoor refrigerator that has a cooling capacity of up to 10 tons, which means you don’t have to worry about running out of space for your drinks.

It is also easy to use and operate and has a high efficiency rate.

– The second on the list is an outdoor refrigerator with a cooling capacity of up to 12 tons, which means you can keep more beverages cold at once without worrying about running out of.

The Importance of Proper Chilling and What You Can Do to Improve Your Chilling Efficiency

The Importance of Proper Chilling and What You Can Do to Improve Your Chilling Efficiency

In the food processing industry, chilling is a crucial process for ensuring food safety.

It also influences the quality of the product.

The right chilling system can help you to get a top-notch chilling process. Here are some steps that you can take to improve your chilling efficiency:

How To Choose an Appropriate Chiller Solution For Your Application

Chiller selection is an important decision for any process industry.

The chiller must be able to meet the needs of the process and the space constraints of the facility.

The first step in selecting a chiller is identifying what size chiller you need.

Chiller sizing can be determined by calculating the tonnage required to maintain your desired temperature, or matching your horsepower requirements with a specific tonnage rating.

When you have identified which size chiller you need, it is time to identify which type of chiller will work best for your application.

There are two types of chillers: air-cooled chillers and water-cooled chillers.

They each have their own benefits and drawbacks that should be considered when making a final decision on which one to purchase.

How to Choose the Right Portable Chiller for the Specific Location and Application Needs

Some people believe that the best way to cool down is by taking a dip in the pool.

This may be true in some cases but not all.

If you are looking for a more practical and efficient way to cool down, then investing in a portable chiller might be your best option.

A portable chiller is an air-cooled refrigeration system that can be used for different applications, depending on its size.

It is usually installed outside of buildings, where it can take advantage of the ambient temperature.

This type of chiller is typically used for cooling water systems or other processes that require low temperatures.

GESON is a company that is in the business of manufacturing chiller and refrigeration equipment.

They have been in this industry for over 10 years now and they have seen all kinds of trends come and go. However, they always make sure to stay updated with the latest trends in the field so that they can provide their customers with the best possible service.

One of the most recent trends that has taken over this industry is energy efficiency.

With new regulations coming into place, companies are trying to keep up by making their products as efficient as possible.

GESON Chillers are one such company who has taken this trend head on and created a product that can be used for large industrial plants or small restaurants alike!

The GESON Chillers are designed to save energy by being more efficient

Call us today at 0086-13851950629